2025 Top 10 Innovations in Plastic Injection Molding You Can't Miss

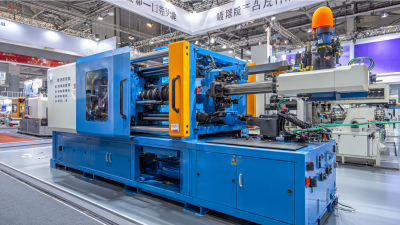

In the rapidly evolving field of manufacturing, the plastic injection molding industry stands at the forefront of innovation. As we look ahead to 2025, industry experts predict groundbreaking advancements that will reshape the way products are designed and produced. Renowned plastic injection molding expert, Dr. Emily Carter, notes, “The future of plastic injection technology lies in its ability to enhance efficiency while minimizing environmental impact.” This pivotal statement underscores the necessity for industry professionals to stay informed about upcoming trends and innovations that can significantly affect their practices.

As we explore the top ten innovations set to make waves by 2025, we will delve into advancements in materials, techniques, and technology that promise to redefine efficiency, sustainability, and product versatility. From the integration of AI-driven processes to the use of biodegradable plastics, understanding these developments is crucial for staying competitive in the plastic injection molding sector. The journey to 2025 is not just about keeping pace with change but embracing it, ensuring that manufacturers can meet the demands of both market and consumers in a responsible manner. Prepare to discover the innovations you can't afford to miss in this dynamic industry.

Revolutionary Materials: Biodegradable Plastics in Injection Molding

As the world increasingly seeks sustainable solutions, biodegradable plastics are emerging as a game-changer in the field of plastic injection molding. These innovative materials offer an eco-friendly alternative to traditional plastics, breaking down more quickly and minimizing environmental impact. The use of biodegradable plastics in injection molding not only meets the growing consumer demand for sustainability but also presents opportunities for manufacturers to differentiate their products in a competitive market.

Tip: When considering biodegradable options, ensure that the materials are suitable for your specific application. Different biodegradable plastics have varying properties, so it’s essential to test them under the intended conditions to determine their performance.

Moreover, incorporating biodegradable materials into the injection molding process does not compromise quality or efficiency. New advancements in technology allow for seamless integration, enabling manufacturers to produce durable and high-performing products that are also environmentally friendly. This trend indicates a shift in industry standards, with more companies moving towards sustainable practices.

Tip: Stay updated with the latest material innovations and industry trends. Collaborating with suppliers who specialize in biodegradable options can provide valuable insights and help streamline the transition to greener production methods.

Smart Automation: AI-Powered Robotics Transforming Production Lines

The landscape of plastic injection molding is undergoing a revolutionary transformation with the integration of smart automation and AI-powered robotics. According to a report by MarketsandMarkets, the global AI in manufacturing market is projected to reach $16.7 billion by 2026, showcasing a compound annual growth rate (CAGR) of 53.7%. As manufacturers strive for efficiency, AI-driven robots are streamlining production lines, enhancing precision, and significantly reducing cycle times.

Robotics equipped with AI capabilities can adapt to fluctuating production demands, learning from data to optimize processes in real-time. This results not only in enhanced outcomes but also in substantial cost savings. A study by McKinsey highlights that AI adoption in manufacturing could increase productivity by up to 30% by 2030. As plastic injection molding firms embrace this technology, they can improve their production efficiency, reduce material waste, and minimize human error, thus paving the way for a more sustainable manufacturing future. The innovative potential of AI-powered robotics is set to reshape the traditional paradigms of injection molding, making it an essential focus for industry stakeholders in the coming years.

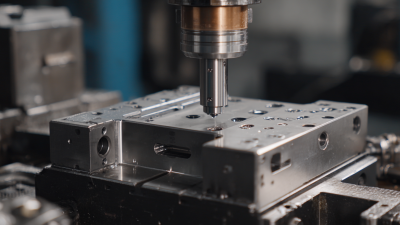

Enhanced Design Software: 3D Modeling Innovations for Molding Efficiency

The landscape of plastic injection molding is rapidly evolving, particularly with the introduction of enhanced design software that leverages 3D modeling innovations. These advanced tools are revolutionizing how engineers and designers approach the molding process. By providing highly detailed and accurate visualizations, 3D modeling software allows for better assessment of designs before production, significantly reducing the likelihood of errors and costly modifications. This preemptive design validation streamlines processes and enhances overall efficiency.

Additionally, the integration of parametric modeling has transformed the customization capabilities of plastic injection molds. Designers can easily manipulate variables and generate multiple prototypes in a fraction of the time it previously took. This agility not only accelerates the product development cycle but also fosters creativity by enabling rapid experimentation with different configurations. As a result, manufacturers can respond more swiftly to market demands and consumer preferences. The investment in such innovative software solutions is quickly becoming a necessity for businesses aiming to maintain a competitive edge in the evolving landscape of plastic injection molding.

Sustainable Practices: Circular Economy Approaches in Injection Molding

One of the most significant advancements in plastic injection molding is the integration of sustainable practices, particularly focusing on circular economy approaches. The circular economy emphasizes the importance of designing products for longevity, reuse, and recyclability, which is crucial in addressing the environmental challenges posed by traditional plastic production. By utilizing recycled materials and optimizing the manufacturing process to minimize waste, companies can significantly reduce their carbon footprint while maintaining efficiency and product quality.

Innovations such as bio-based plastics and energy-efficient machinery are becoming increasingly popular in the injection molding industry. These materials not only help in reducing reliance on fossil fuels but also offer the potential for end-of-life recovery, allowing businesses to reintegrate materials back into the production cycle. Furthermore, adopting digital technologies, such as IoT sensors and real-time data analytics, allows manufacturers to monitor and improve their operations continuously, leading to smarter resource management and enhanced sustainability in the long run. Embracing these circular economy principles is essential for the future of injection molding, aligning business goals with environmental responsibility.

2025 Innovations in Plastic Injection Molding: Sustainable Practices

Advanced Quality Control: Real-Time Monitoring Systems for Flawless Production

The landscape of plastic injection molding is undergoing a significant transformation, with advanced quality control methods taking center stage. The introduction of real-time monitoring systems is revolutionizing production processes by ensuring that every component meets stringent quality standards. These systems utilize cutting-edge technologies to provide immediate feedback on various parameters during manufacturing, allowing for quick adjustments and minimizing defects. As industries strive for higher efficiency and reliability, these innovations become essential in maintaining competitive advantages.

In parallel, the global market for BOF slag detection systems is expected to reach a valuation of $3.397 billion by 2025, with a robust CAGR projected to reach $5.74 billion by 2033. This growth underscores the increasing demand for precise monitoring technologies across different sectors, reflecting a broader trend toward automation and data-driven decision-making. The integration of these high-tech solutions not only enhances quality control in plastic injection molding but also contributes to overall operational excellence in industrial production.

Related Posts

-

Exploring the Differences Between Plastic Injection Molding and Other Manufacturing Processes

-

Understanding the Future of Manufacturing: Innovations in Plastic Injection Tooling Technology

-

Exploring the Innovations in Plastic Injection Technology for a Sustainable Future

-

Challenges Faced in Injection Tooling Manufacturing Process

-

How to Master the Art of Plastic Casting for Innovative Product Design

-

Driving Innovation in Injection Tooling at the 138th Canton Fair 2025 with Industry Data Insights

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering