Top 10 Benefits of Using Plastic Injection Molding Dies for Your Projects

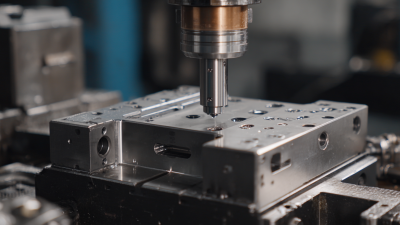

In the rapidly evolving landscape of manufacturing, the significance of employing efficient production methods cannot be overstated. One such method that has gained immense popularity is the use of plastic injection molding dies. Industry expert Dr. Emily Carter, a renowned figure in the field of polymer processing, once noted, "The precision and versatility of plastic injection molding dies are unparalleled, allowing manufacturers to achieve complex designs with remarkable efficiency." This statement encapsulates the essence of why businesses are increasingly integrating this technique into their operations.

Plastic injection molding dies not only streamline the production process but also offer a multitude of advantages that can enhance product quality and reduce overall costs. From minimizing waste to enabling rapid production cycles, the benefits associated with this method are compelling for manufacturers looking to optimize their processes. As we delve deeper into the top ten benefits of using plastic injection molding dies for your projects, it becomes clear that this technology stands at the forefront of modern manufacturing solutions, positioning companies to meet the demands of an ever-competitive market.

Benefits of Enhanced Production Speed Through Injection Molding Techniques

Injection molding is a revolutionary manufacturing process that significantly enhances production speed, earning it a prominent position in modern industrial applications. One of the primary benefits of using plastic injection molding dies is their ability to produce large quantities of parts in a fraction of the time compared to traditional manufacturing methods. The automated nature of injection molding allows for rapid cycle times, wherein the same part can be produced continuously with minimal interruptions. This efficiency not only accelerates production but also helps meet the growing demands of various industries swiftly.

Moreover, the precision and consistency offered by injection molding contribute to its enhanced production speed. Advanced molds can be engineered to tight tolerances, ensuring that each part is uniform and of high quality. This level of precision reduces the need for extensive post-production modifications, saving additional time and resources. As a result, manufacturers can achieve high throughput rates while maintaining quality standards, which is crucial in competitive markets. The combination of speed and accuracy makes plastic injection molding an invaluable technique for projects that require rapid scaling and enhanced efficiency.

Top 10 Benefits of Using Plastic Injection Molding Dies for Your Projects

| Benefit | Description | Impact on Production |

|---|---|---|

| Enhanced Production Speed | Injection molding allows for rapid production of parts with high precision. | Increased output rates with reduced cycle times. |

| Cost Efficiency | Lower cost per part due to high-speed manufacturing and reduced waste. | Lower production costs enhance profit margins. |

| Complex Shapes | Ability to create intricate designs that are difficult to achieve with other methods. | Allows for innovative product designs. |

| Material Versatility | Supports a wide variety of thermoplastic materials. | Flexibility in design choices and applications. |

| High Precision and Consistency | Injection molding produces parts with tight tolerances. | Ensures uniformity in product quality. |

| Reduced Labor Costs | Automation of the injection molding process lowers labor needs. | Streamlines operations and reduces overhead. |

| Minimized Waste | Efficient material usage results in less scrap waste. | Improves sustainability and reduces costs. |

| Fast Prototyping | Quick turnaround time for creating prototype parts. | Accelerates product development cycles. |

| Scalability | Easy to scale up production for larger runs. | Supports business growth and market expansion. |

| Durability of Parts | Injection-molded parts are known for their strength and durability. | Increases product lifespan and customer satisfaction. |

Cost Efficiency in Mass Production with Plastic Injection Molding Dies

Plastic injection molding is a widely used manufacturing process that offers significant cost efficiency, particularly in mass production scenarios. According to a report by the American Society of Mechanical Engineers, plastic injection molding can reduce production costs by up to 30% compared to traditional manufacturing methods. This is primarily due to lower material costs and shortened production cycles. The ability to create complex shapes and intricate designs with high precision in a single step further enhances savings, as it minimizes material waste and reduces the need for secondary operations.

In mass production, the use of injection molding dies allows for high-volume output with consistent quality. Industry studies indicate that injection molding can produce thousands of parts per hour, making it an ideal choice for manufacturers looking to scale operations quickly. A study published by the Society of Plastics Engineers notes that using plastic injection molding can lead to a reduction in labor costs by 15-20%, as automated systems require less manual intervention. Furthermore, the durability of the injection molding dies means that initial investments yield long-term benefits, as these dies can withstand significant production runs, lowering the per-unit cost over time.

Top 10 Benefits of Using Plastic Injection Molding Dies

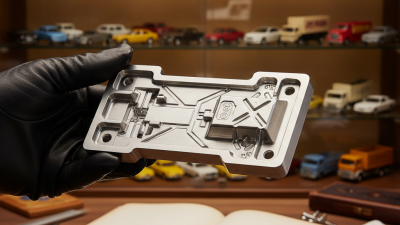

Precision and Accuracy Achieved with Advanced Molding Technologies

The adoption of advanced molding technologies in plastic injection molding has significantly enhanced precision and accuracy in manufacturing processes. According to a report by the Plastics Industry Association, advancements in injection molding technologies have improved tolerances by up to 0.001 inches, enabling manufacturers to produce components that meet rigorous industry standards with minimal deviation. This level of precision is vital in sectors such as automotive and aerospace, where small discrepancies can lead to significant performance issues or safety risks.

Moreover, the ability to produce complex geometries with high consistency has become increasingly achievable through state-of-the-art molding techniques. Research published by the American Society of Mechanical Engineers highlights that modern injection molding machines are now capable of variable cooling rates and optimized cycle times, which contribute to enhanced dimensional stability and surface finish in molded parts. These advancements not only reduce the likelihood of defects but also decrease the time and costs associated with secondary operations, driving efficiency in production workflows. As industries continue to seek innovative solutions, the role of precision and accuracy in injection molding is more critical than ever.

Versatility of Materials: Expanding Design Possibilities in Injection Molding

The versatility of materials in plastic injection molding significantly expands design possibilities, making it an invaluable technique in product development. Unlike traditional manufacturing methods, injection molding allows for the use of a vast range of materials, including thermoplastics, thermosetting plastics, and elastomers. This flexibility enables designers to select materials that not only meet functional requirements—such as durability, heat resistance, and flexibility—but also enhance aesthetic qualities with varied colors and finishes. As a result, manufacturers can create complex and detailed designs that might be impractical or impossible with other methods.

Moreover, the ability to customize material properties facilitates innovation in product design. By blending different plastic types or incorporating additives, engineers can tailor materials to specific applications, improving performance while reducing weight and costs. This adaptability is particularly beneficial in industries such as automotive, consumer goods, and medical devices, where strict performance criteria must be met. By harnessing the versatility of materials, businesses can not only streamline their production processes but also continually push the boundaries of design, ultimately leading to more competitive and market-ready products.

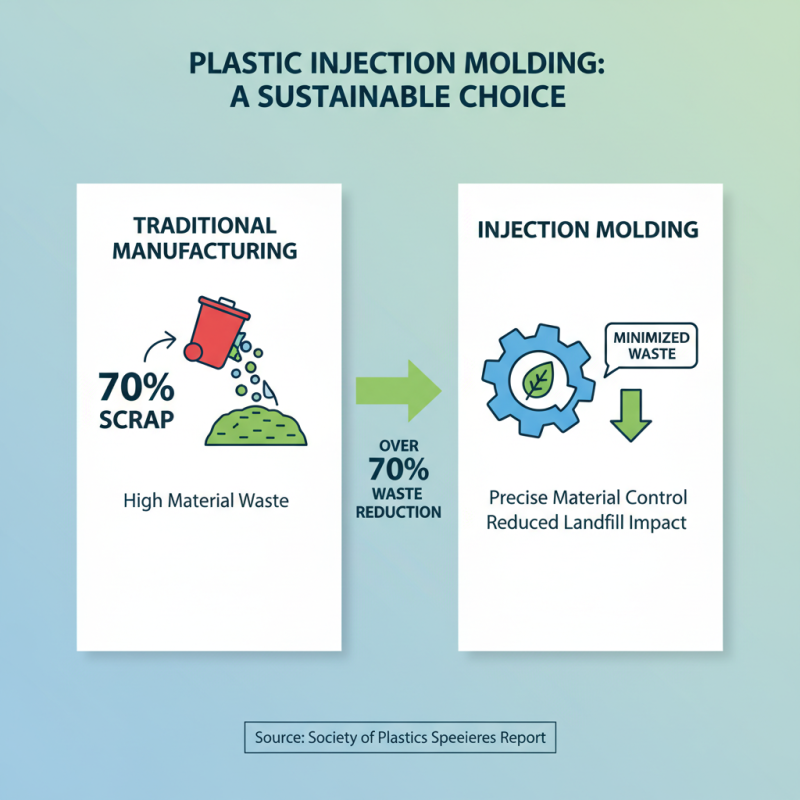

Sustainability Advantages: Reducing Waste in Plastic Manufacturing Processes

Plastic injection molding is increasingly recognized for its sustainability benefits, particularly in minimizing waste throughout the manufacturing process. According to a report by the Society of Plastics Engineers, over 70% of plastic products generated through traditional manufacturing methods result in scrap material, which often ends up in landfills. However, utilizing injection molding dies can significantly reduce this waste. With precise control over material consumption, manufacturers can optimize the amount of plastic used, leading to a reduction in excess and scrap material.

Furthermore, plastic injection molding has the capability to use recycled materials, further enhancing its sustainability profile. The American Chemistry Council estimates that nearly 30% of injected molded plastics come from recycled content. This integration of recycled materials not only lowers the environmental footprint but also promotes a circular economy in plastics, allowing manufacturers to produce new items without relying entirely on virgin resources. As industries continue to adopt green practices, the shift towards plastic injection molding dies represents a critical step in fostering sustainable manufacturing processes that align with both environmental goals and economic efficiency.

Related Posts

-

5 Tips on Enhancing Tool and Die Precision with 20 Percent Increased Efficiency

-

Ultimate Guide to Mastering Die Cast Tooling for Efficient Production

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

2025 Top Die Cast Die Tips for Collectors and Enthusiasts

-

Unlocking Precision: The Science Behind Die Cast Tooling in Modern Manufacturing

-

Challenges Faced in Injection Tooling Manufacturing Process

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering