Challenges Faced in Injection Tooling Manufacturing Process

The injection tooling manufacturing process plays a crucial role in the production of high-quality plastic parts, yet it comes with a myriad of challenges that can impact efficiency and cost-effectiveness. According to a recent report by Allied Market Research, the global injection molded plastics market is projected to reach $385.3 billion by 2027, underscoring the growing demand in various industries, including automotive, consumer goods, and medical devices.

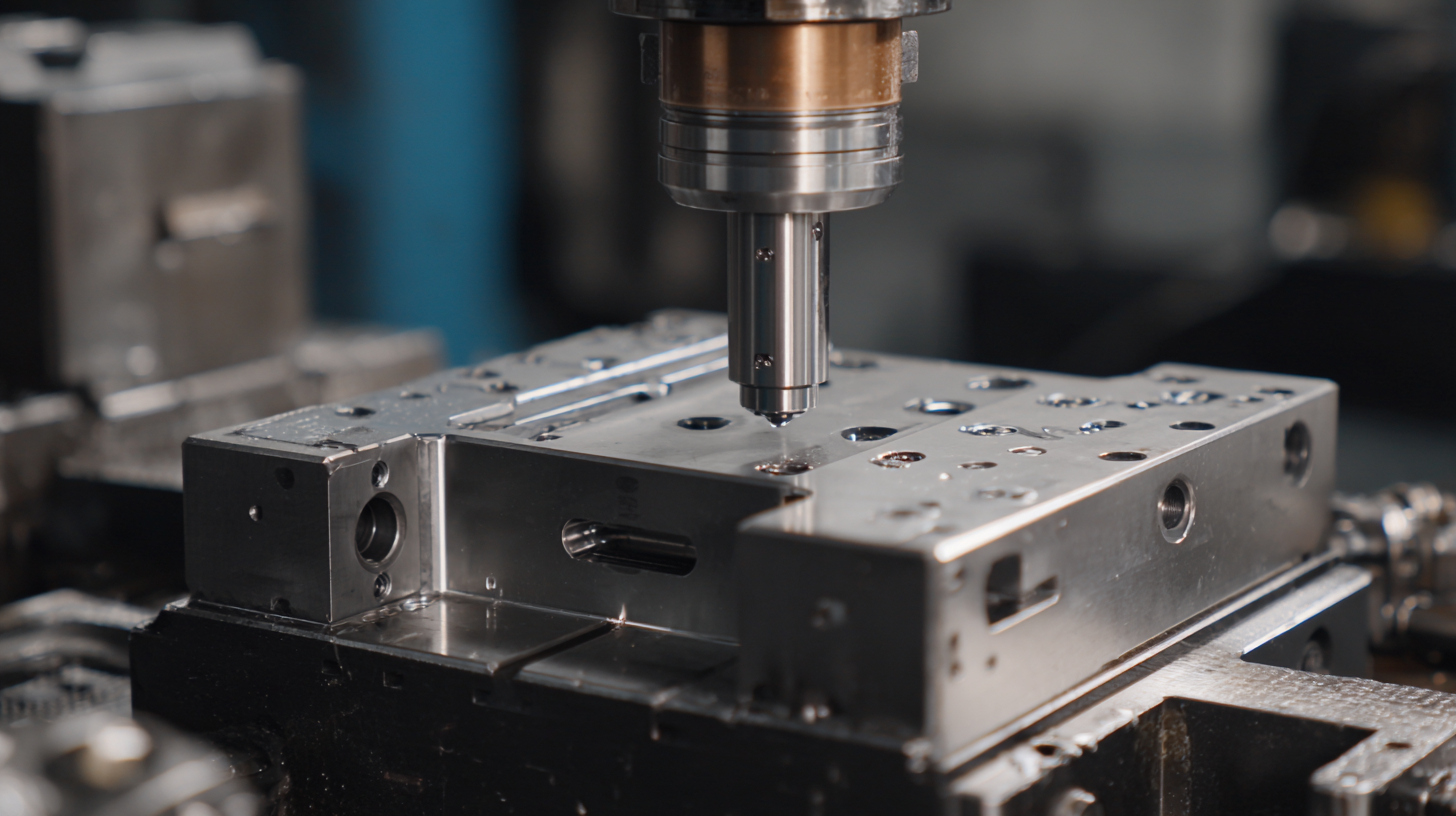

However, with this surge in demand also arises the need for precision in injection tooling design and fabrication, as even minor defects can lead to substantial losses. Factors such as material selection, mold design complexity, and the need for rapid prototyping further complicate the injection tooling process. Addressing these challenges is imperative for manufacturers aiming to stay competitive in a fast-evolving marketplace, making an in-depth understanding of the injection tooling manufacturing process indispensable for success.

Identifying Key Challenges in Injection Tooling Manufacturing

The injection tooling manufacturing process faces several key challenges that can significantly impact efficiency and product quality. Firstly, identifying and rectifying tool design deficiencies is crucial, as early detection can prevent costly errors and improve the overall performance of the manufactured parts. For instance, issues like dimensional inaccuracies or suboptimal cooling settings can lead to increased scrap rates and production downtime. Implementing systematic evaluations and employing innovative techniques, such as simulation-driven design optimization, is essential in addressing these shortcomings.

Moreover, as the industry continues to evolve, the integration of advanced technologies such as artificial neural networks and genetic algorithms has emerged as a game-changer for optimizing the injection molding process. These hybrid optimization approaches can enhance decision-making and streamline operations, ultimately leading to improved productivity. Additionally, the adoption of innovative cooling methods, like using liquified CO2, demonstrates a growing commitment within the manufacturing sector to reduce cycle times and minimize energy consumption. As the demand for high-quality plastic components increases, addressing these challenges remains a top priority for manufacturers seeking to maintain competitiveness in the market.

The Role of Advanced Technologies in Overcoming Injection Tooling Issues

The manufacturing of injection tooling is fraught with various challenges, primarily centered around precision, material selection, and production efficiency. Recent advancements in technology, particularly those emerging from Industry 5.0 principles, are transforming these obstacles into opportunities. For instance, Additive Digital Molding is being employed to enhance business agility and sustainability in supply chains, enabling manufacturers to produce more complex mold designs with reduced lead times. This technology allows for rapid prototyping and iterative design, essential in meeting the evolving demands of industries such as aerospace and automotive, where lightweight and efficient components are crucial.

Furthermore, the integration of advanced materials, including lightweight composites and high-strength alloys, is critical in improving the performance of injection molds. A systematic review in the automotive sector highlights that utilizing advanced materials can lead to a significant reduction in product weight and enhancement in overall structural integrity, making them suitable for high-performance applications. These innovations not only resolve traditional issues within the injection tooling process but also align with sustainable development goals, ultimately fostering a more resilient manufacturing ecosystem. The collaborative efforts between material science and digital technologies are paving the way for a new era in injection tooling, demonstrating the vital role that advanced technologies play in overcoming longstanding manufacturing challenges.

Challenges Faced in Injection Tooling Manufacturing Process

| Challenge | Description | Advanced Technology Solutions |

|---|---|---|

| Material Variability | Inconsistent raw material properties leading to defects. | Use of material characterization technologies to ensure uniformity. |

| Precision Tolerance | Difficulty in maintaining precision during the molding process. | Adoption of high-precision CNC machining and robotic automation. |

| Cycle Time Reduction | Need to shorten production time while maintaining quality. | Implementation of simulation software for process optimization. |

| Tool Wear | Excessive wear of tooling impacting productivity and costs. | Utilizing advanced coatings and predictive maintenance technologies. |

| Quality Control | Ensuring consistent part quality throughout production runs. | Incorporating real-time monitoring and quality assurance systems. |

Quality Control Measures for Effective Injection Tooling Processes

Quality control is paramount in the injection tooling manufacturing process, ensuring that products meet stringent specifications and client expectations. According to a report from the Society of Plastics Engineers, nearly 30% of defects in injection-molded parts can be traced back to insufficient quality control during the tooling phase. This indicates that implementing robust quality control measures is not just beneficial but essential for streamlining production and reducing waste.

To enhance quality control in injection tooling, manufacturers should invest in advanced inspection technologies. Techniques such as automated laser scanning and 3D measurement can detect inconsistencies early, thus preventing costly modifications later in the process. Regular training for staff on quality standards is equally important. A recent survey indicates that companies that provide ongoing quality control training observed a 25% decrease in defect rates.

**Tip 1:** Establish clear benchmarks for quality at every stage of the tooling process to ensure consistency and reliability in production.

**Tip 2:** Implement a feedback loop where operators can report issues or suggestions, fostering an environment of continuous improvement and accountability throughout the manufacturing process.

Cost Management Strategies in Injection Tooling Manufacturing

Cost management is a crucial aspect of injection tooling manufacturing, as it directly influences the overall profitability and efficiency of production. One of the primary challenges manufacturers face is the high initial investment in tooling and machinery, which can be a barrier for smaller companies. To mitigate these costs, businesses can adopt strategies such as optimizing their design processes and utilizing advanced software for simulations, which helps to identify potential issues early in the tooling phase. This proactive approach not only reduces the likelihood of costly redesigns but also enhances product quality.

Another effective strategy is the implementation of lean manufacturing principles. By focusing on waste reduction and continuous improvement, manufacturers can streamline operations and minimize expenses. For instance, analyzing the production workflow may reveal redundancies or inefficiencies that can be addressed to save time and resources. Additionally, investing in employee training and skill development can lead to improved performance and innovation within the workforce, further supporting cost management efforts. Ultimately, a combination of innovative design techniques and lean practices can help injection tooling manufacturers navigate the financial challenges of their industry.

Challenges Faced in Injection Tooling Manufacturing Process - Cost Management Strategies

Future Trends: Innovations in Injection Tooling to Address Current Challenges

The injection tooling manufacturing process is experiencing significant transformations driven by technological advancements and market demands. Innovations such as 3D printing and advanced materials are redefining how tools are designed and produced. These new methods not only reduce lead times but also improve precision and durability. Companies are increasingly adopting smart manufacturing technologies, allowing for real-time monitoring and optimization of the tooling processes.

To effectively navigate these changes, businesses can adopt a flexible approach. Tips for successful integration of innovations include investing in training for staff to ensure they are comfortable with new technologies, and maintaining open communication with suppliers to keep up with the latest advancements in materials and techniques. Regularly assessing production processes for potential improvements can lead to significant efficiency gains.

Moreover, sustainability is becoming a crucial focus in injection tooling. Manufacturers are exploring eco-friendly materials and processes to minimize waste and energy consumption. By implementing circular economy principles, businesses can not only address regulatory challenges but also appeal to a growing customer base that values sustainability. Keeping abreast of these trends is essential for staying competitive in the evolving landscape of injection tooling.

Related Posts

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

Best Die Cast Solutions: Enhancing Precision and Efficiency in Manufacturing

-

Mastering the Essentials of Plastic Injection Molding Die Design and Production Guide

-

Top 5 Innovative Die Cast Equipment Examples Revolutionizing Manufacturing Efficiency

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering