How to Choose the Right Die Cast Mold for Your Manufacturing Needs

In today's manufacturing landscape, the precision and efficiency of production processes greatly hinge on selecting the right die cast mold. According to a recent industry report by Smithers Pira, the global die casting market is projected to reach USD 80 billion by 2026, driven by rising demands in automotive and consumer electronics sectors.

As manufacturers strive to enhance productivity and quality, understanding the nuances of die cast mold selection becomes imperative. Factors such as material compatibility, design complexity, and thermal stability play crucial roles in ensuring optimal performance and cost-effectiveness.

By making informed decisions about die cast molds, manufacturers can not only improve product outcomes but also streamline operational workflows, thereby securing a competitive edge in an ever-evolving market.

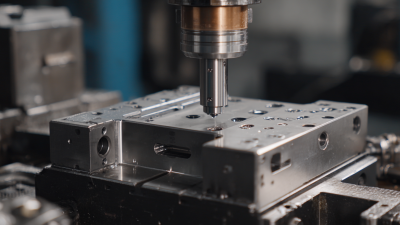

Understanding the Basics of Die Casting and Mold Types

Die casting is a crucial manufacturing process that involves forcing molten metal into a mold to create precise and intricate components. Understanding the various types of die casting molds is essential for selecting the right one for your manufacturing needs. The two main types of molds are permanent and expendable. Permanent molds are made from durable materials like steel or iron, and they are used for high-volume production, allowing for greater precision and longevity in the manufacturing process. Expendable molds, on the other hand, are typically made of sand or other materials and are ideal for lower production runs where the flexibility of design is more critical than the longevity of the mold itself.

Choosing the appropriate mold type hinges on several factors, including production volume, the complexity of the component, and the desired finish quality. For high production rates, permanent molds can reduce overall costs and enhance precision, while expendable molds may be preferable for prototypes or specialized designs requiring frequent changes. Therefore, understanding the specific requirements of your project will lead to better decision-making in mold selection, ultimately impacting the efficiency and success of your manufacturing operations.

Key Factors to Consider When Choosing a Die Cast Mold

When selecting the right die cast mold for your manufacturing needs, several key factors should be taken into consideration. First and foremost is the material of the mold itself. Molds are typically made from steel or aluminum, each offering distinct advantages. Steel molds are more durable and ideal for high-volume production runs, while aluminum molds are lighter and better suited for lower volume projects due to their quicker turnaround time.

Another crucial factor to consider is the complexity of the part being produced. Intricate designs may require molds with advanced features such as cores and slides to ensure precision. Additionally, the cooling system integrated into the mold plays a significant role in production efficiency. An optimized cooling system reduces cycle times and improves part quality, which can significantly impact overall manufacturing productivity. Understanding these factors will help you make an informed decision, aligning your mold choice with your production goals.

Comparing Material Options for Die Cast Molds: Pros and Cons

When selecting the right die cast mold for manufacturing, one of the most critical decisions involves the material options available. Common materials for die casting molds include steel, aluminum, and copper, each presenting its advantages and disadvantages.

Steel molds, for example, offer exceptional durability and heat resistance, making them ideal for high-volume production runs. However, their higher upfront costs can be a detriment for smaller operations or projects with limited budgets.

Steel molds, for example, offer exceptional durability and heat resistance, making them ideal for high-volume production runs. However, their higher upfront costs can be a detriment for smaller operations or projects with limited budgets.

On the other hand, aluminum molds are lighter and provide faster heat dissipation, which can enhance cycle times and reduce production costs in the long run. They are particularly suitable for low to medium-volume runs, although they may wear out more quickly than their steel counterparts, necessitating more frequent replacements.

Copper molds, known for their superior thermal conductivity, offer an excellent middle ground, combining low thermal expansion with high strength. However, the cost and complexity of manufacturing copper molds can limit their use to specific applications where performance is paramount.

Understanding these material properties is crucial for manufacturers to make informed decisions that align with their production goals and budget constraints.

Analyzing Production Volume Needs for Optimal Mold Selection

When choosing the right die cast mold for your manufacturing needs, it is essential to analyze your production volume requirements. This analysis helps ensure that the selected mold is not only effective but also cost-efficient. High production volumes may justify investing in a more robust mold design that can withstand wear and provide consistent quality over time. In contrast, lower volume production might benefit from a less complex mold, reducing initial costs without sacrificing quality.

**Tip 1:** Consider your future scaling needs. If your production volume is expected to increase, selecting a mold that can accommodate higher capacities will save you from re-investing in new molds later.

Additionally, evaluating the materials you plan to work with can significantly influence your mold selection. Different materials may require specific mold designs to optimize melting and cooling times, impacting overall production efficiency. Understanding the thermal properties and behavior of your chosen materials can aid in making a more informed decision.

**Tip 2:** Consult with mold-making experts to gain insights on material compatibility and mold design innovations that can support your production volume goals. Having expert advice can streamline your selection process and lead to greater production success.

How to Choose the Right Die Cast Mold for Your Manufacturing Needs - Analyzing Production Volume Needs for Optimal Mold Selection

| Production Volume Range | Mold Material Type | Mold Lifespan (Cycles) | Mold Cost (USD) | Recommended Application |

|---|---|---|---|---|

| 1,000 - 5,000 | Aluminum | 50,000 | $5,000 | Prototype Components |

| 5,000 - 20,000 | Steel | 100,000 | $10,000 | Medium Volume Production |

| 20,000 - 100,000 | Nickel-Plated Steel | 200,000 | $20,000 | High Volume Production |

| 100,000+ | Hardened Steel | 500,000 | $50,000 | Mass Production |

Cost vs. Quality: Finding the Balance in Die Cast Molds

When selecting the appropriate die cast mold for your manufacturing needs, a critical aspect is balancing cost against quality. High-quality molds can significantly reduce defect rates and improve the overall durability of the finished product, ultimately resulting in lower rejection rates and enhanced productivity. A recent study indicates that optimizing mold design can lead to a 30% increase in production efficiency and a notable reduction in defects associated with casting processes.

**Tip:** When evaluating molds, consider not just the initial cost but the long-term benefits of durability and maintenance. Invest in molds that have proven longevity and can withstand the stresses of high-pressure die casting without compromising quality.

Additionally, advancements in die casting technologies are making it possible to produce larger and more complex parts while maintaining high standards. Industries are witnessing the rise of mega-castings, which can replace multiple components with a single casting, enhancing structural integrity and reducing assembly costs. Reports suggest that adopting machine learning for mold optimization can lead to improved cycle times and part quality, making it imperative for manufacturers to stay updated with the latest technological trends.

**Tip:** Collaborate with industry experts and invest in ongoing training for your team to ensure they are equipped to leverage new technologies effectively, maximizing both productivity and quality in your die casting processes.

Related Posts

-

Mastering the Essentials of Plastic Injection Molding Die Design and Production Guide

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

Top 5 Innovative Die Cast Equipment Examples Revolutionizing Manufacturing Efficiency

-

Best Die Cast Solutions: Enhancing Precision and Efficiency in Manufacturing

-

Challenges Faced in Injection Tooling Manufacturing Process

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering