What is Die Cast and How is it Used in Manufacturing and Collectibles

Die cast is a manufacturing process that has gained popularity for its versatility and precision in producing detailed and complex products. This method involves forcing molten metal into a mold under high pressure, resulting in pieces that exhibit excellent dimensional accuracy and surface finish. Die casting is not only utilized in various industrial applications but also plays a significant role in the world of collectibles. From automotive models to miniature figures, die cast items often attract collectors due to their craftsmanship and attention to detail.

In the realm of manufacturing, die cast components are favored for their lightweight nature and the ability to create intricate designs that would be difficult or impossible to achieve with other methods. The process allows for high-volume production while minimizing waste, making it an efficient choice for many industries. Meanwhile, the collectible market revels in the artistry of die cast models, with enthusiasts valuing the unique features and quality that come with these finely crafted pieces.

As we delve into the intricacies of die cast, we will explore how this process is employed across various sectors and the allure it holds for collectors. Understanding the significance of die cast not only highlights its practical applications but also its place in the hearts of aficionados and hobbyists alike.

What is Die Casting? Definition and Process Overview

Die casting is a manufacturing process in which molten metal is injected into a mold under high pressure. This method is extensively used for producing complex shapes with high precision and excellent surface finish. Typically, metals such as aluminum, zinc, and magnesium are used in die casting, as they possess favorable flow characteristics and can solidify quickly. The process begins with the creation of a die, which is a two-part mold made from steel or other materials capable of withstanding the intense pressure and heat of the molten metal.

Once the die is prepared, the molten metal is injected, filling the mold cavities rapidly. After the metal cools and solidifies, the die is opened to eject the finished part. This process not only allows for high-volume production but also enables designers to incorporate intricate details in the final products.

Die casting is favored in various industries, including automotive, aerospace, and consumer goods, due to its efficiency and ability to produce lightweight yet durable components. The versatility of die casting also extends to collectibles, where detailed replicas and models can be manufactured, satisfying both aesthetic and functional needs.

Materials Used in Die Casting: Types and Properties

Die casting is a widely used manufacturing process that involves forcing molten metal into a mold cavity. The choice of materials for die casting plays a crucial role in the quality of the final product. Common materials used in die casting include aluminum, zinc, magnesium, and copper-based alloys. According to a recent market report, aluminum die casting is forecasted to account for over 80% of the die casting market by 2025 due to its excellent strength-to-weight ratio and corrosion resistance.

Aluminum die castings typically exhibit high thermal and electrical conductivity, making them ideal for automotive and electronic applications. Zinc die casting is noted for its exceptional fluidity and ability to fill complex shapes, thus reducing the need for machining. Magnesium, while lighter than both aluminum and zinc, offers superior dimensional stability and is becoming increasingly popular in aerospace applications. Each material has distinct properties, such as melting point and tensile strength, which directly affect the design and manufacturing processes.

Tip: When selecting a material for die casting, consider the intended application and environmental factors. For instance, if weight reduction is critical, aluminum or magnesium may be preferable. Additionally, ensure that the selected alloy meets the required mechanical properties to maintain product durability.

The Die Casting Process: Step-by-Step Breakdown

The die casting process is a highly efficient manufacturing technique used to create metal parts with precision and detail. It involves several critical steps that ensure the integrity and quality of the finished pieces. The first step is the preparation of the die, which is typically made from steel or other durable materials. The die is meticulously crafted to shape the desired part, including any intricate designs. Once the die is ready, it is cleaned and coated with a release agent to facilitate easy removal of the castings.

The next phase is the melting and pouring of molten metal into the die. Aluminum, zinc, and magnesium are common materials used in die casting due to their favorable properties. The molten metal is injected into the die under high pressure, filling every corner of the mold to capture even the finest details. After allowing the metal to cool and solidify, the die is opened to extract the finished part. This process not only enhances the production speed but also minimizes waste, making die casting an economical choice for high-volume manufacturing and collectible items alike.

Subsequent steps include trimming excess metal and any necessary surface finishing to achieve the desired aesthetic and functional qualities. Quality control checks are then performed to ensure the parts meet specified standards. This meticulous approach to die casting is what makes it a preferred method for producing intricate designs used in various applications, from automotive parts to consumer goods.

| Application | Material Used | Process Steps | Advantages |

|---|---|---|---|

| Automotive Parts | Aluminum | Mold Preparation, Melting, Injection, Cooling, Ejection | High precision, Complex shapes |

| Consumer Electronics | Zinc | Mold Preparation, Metal Cast, Finishing | Cost-effective, Lightweight |

| Collectible Models | Zinc Alloy | Mold Design, Melting, Injection, Cooling | Detail-oriented, Durable |

| Industrial Equipment | Aluminum Alloys | Mold Creation, Injection, Trimming | Strong, High strength-to-weight ratio |

| Aerospace Components | Magnesium | Mold Treatment, Casting, Finishing | Corrosion-resistant, Lightweight |

Applications of Die Casting in Manufacturing Industries

Die casting is a versatile manufacturing process used extensively across various industries due to its ability to create complex shapes with high precision and repeatability. The process involves forcing molten metal into a mold cavity, resulting in components that are not only lightweight but also exhibit excellent mechanical properties. This method is particularly advantageous in mass production where uniformity and efficiency are paramount. Industries such as automotive, aerospace, and electronics utilize die casting to manufacture critical components, including engine parts, housings, and structural elements.

In the automotive sector, die casting plays a pivotal role in the production of lightweight parts that enhance fuel efficiency and overall vehicle performance. Components like transmission cases, engine blocks, and brackets are commonly produced using this method. Similarly, in the electronics industry, die casting is employed to fabricate intricate housings and enclosures for devices, ensuring durability and enhanced thermal management. The precision and surface finish achievable through die casting allow manufacturers to meet stringent specifications and design requirements, making it a preferred choice for high-volume production across manufacturing industries.

Die Cast Collectibles: Popular Items and Market Trends

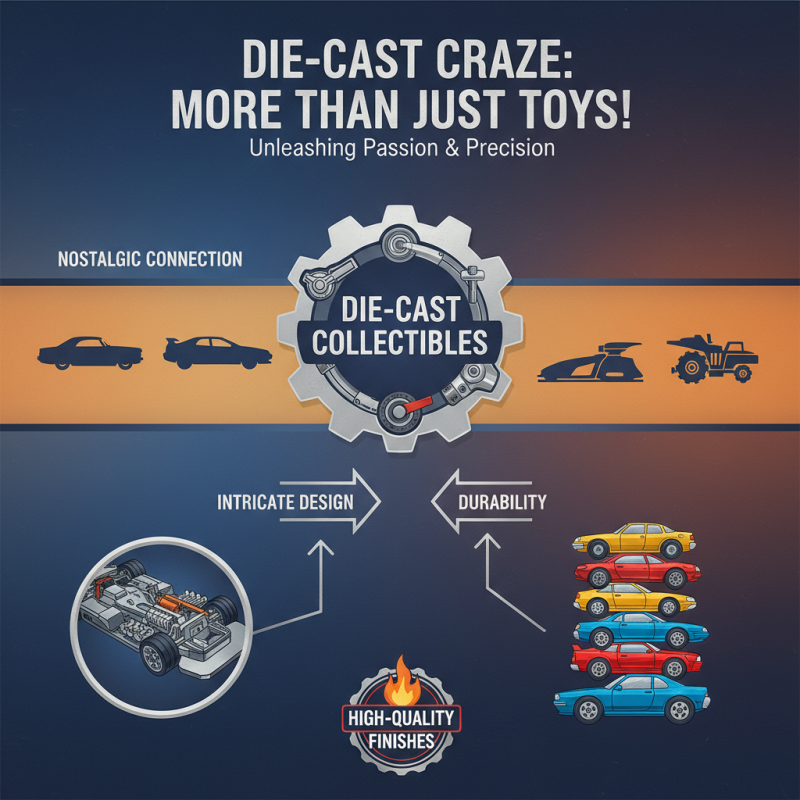

Die cast collectibles have gained immense popularity among enthusiasts and collectors alike, often featuring a wide range of themes, from classic cars to iconic movie vehicles. The die casting process allows for intricate designs and high-quality finishes, making these collectibles both visually appealing and durable. One of the key reasons for their popularity is the nostalgic connection many collectors have with the items, often reminiscing about childhood memories associated with specific models or brands.

Market trends reveal a growing interest in limited edition releases and collaborations with popular franchises, further driving the demand for die cast collectibles. Online marketplaces and auction sites have also contributed to a vibrant secondary market where collectors can buy, sell, and trade rare items. This has allowed for a community-driven approach to collecting, where enthusiasts share tips, showcase their collections, and even attend conventions to connect with others. As new generations discover the joy of collecting die cast models, the market continues to evolve, reflecting both traditional and contemporary interests.

Related Posts

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

The Future of Die Casting: Innovations Shaping Tomorrow's Manufacturing

-

Ultimate Guide to Mastering Die Casting Techniques for Your Business Success

-

10 Insights for Mastering Die Cast Plastic Techniques

-

Ultimate Guide to Mastering Die Cast Tooling for Efficient Production

-

5 Essential Tips for Optimizing Die Cast Die Production Efficiency

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering