Ultimate Die Cast Mold Tips for Perfecting Your Casting Process

In the world of manufacturing and metalworking, the precision and quality of the finished product are paramount, making the die cast mold a critical component in the casting process. A well-designed die cast mold not only enhances the integrity and aesthetic appeal of the castings but also significantly improves production efficiency. Therefore, mastering the nuances of die cast mold design and maintenance is essential for anyone seeking to optimize their casting operations.

This article delves into essential tips for perfecting your casting process, examining aspects such as mold material selection, design considerations, and maintenance practices to ensure exceptional outcomes. By understanding the intricacies involved in die cast mold creation and utilization, practitioners can mitigate common challenges and enhance both productivity and product quality. Whether you're a seasoned expert or a newcomer to the field, these insights will provide valuable strategies to refine your techniques and ultimately achieve casting perfection.

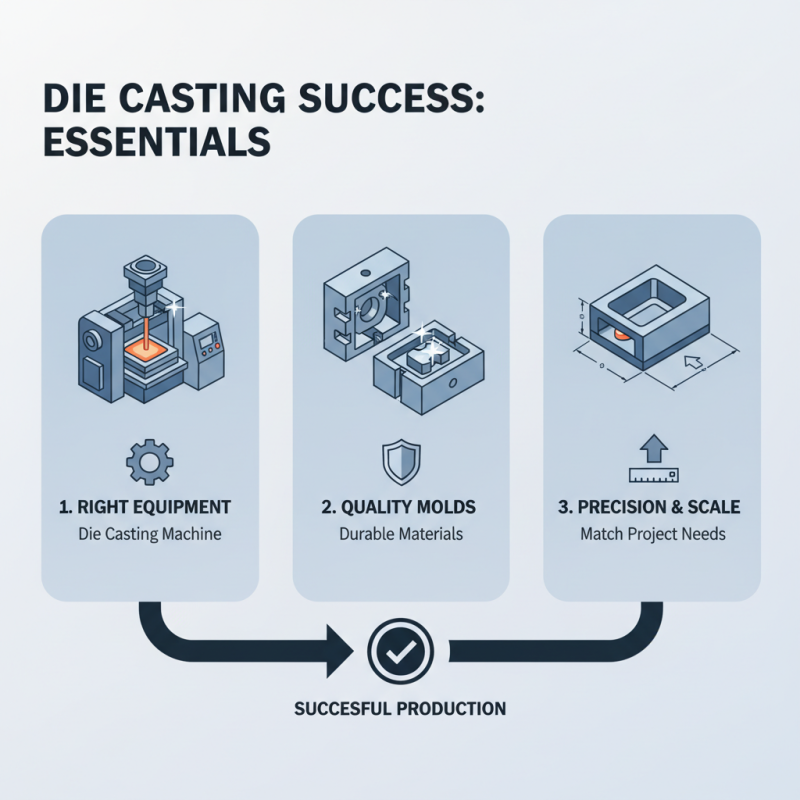

Essential Tools and Equipment for Die Casting Preparation

When preparing for a successful die casting process, having the right tools and equipment is paramount. One of the essential items is the die casting machine itself, which is designed to inject molten metal into molds with precision. It's crucial to select a machine that aligns with the scale and specifications of your casting project. Additionally, the use of high-quality molds is vital; these should be made from durable materials that can withstand repeated production cycles without deforming.

In addition to the main machinery, a variety of supporting tools can enhance the die casting preparation phase. For instance, temperature control devices are important for monitoring and adjusting the temperature of the molten metal to ensure optimal flow characteristics. Moreover, proper ventilation systems should be in place to manage fumes and maintain a safe working environment. Other essential equipment includes cleaning tools to maintain the molds and ensure that no contaminants affect the finished castings. By integrating these essential tools and maintaining them in top condition, the die casting process can be streamlined for efficiency and higher quality output.

Understanding Different Types of Die Cast Molds and Their Uses

When it comes to die casting, understanding the different types of die cast molds and their specific applications is crucial for achieving optimal results. There are generally two main categories of die cast molds: single cavity molds and multi-cavity molds. Single cavity molds are typically used for simpler parts, allowing for precise control over the casting process. They are ideal for low-volume production and ensure high-quality outcomes. On the other hand, multi-cavity molds are designed to produce several identical parts simultaneously, making them more suitable for high-volume production runs.

To enhance efficiency and quality in your casting process, consider these essential tips. First, ensure that your mold is designed with the correct gate size and location to facilitate smooth material flow and minimize turbulence. Additionally, maintaining a proper cooling system within the mold is vital; a consistent temperature prevents defects and ensures uniform solidification. Finally, regularly inspecting and maintaining your molds will prolong their lifespan and enhance the precision of each cast.

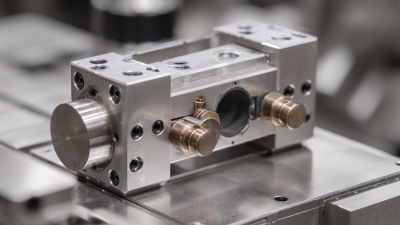

Another significant aspect of die cast molds is the material used in their construction. Common materials include tool steel, which offers excellent durability, and aluminum, known for its lightweight and ease of machining. Selecting the right mold material not only impacts the quality of your casting but also affects the mold's longevity and overall cost-effectiveness in production. Understanding these factors will empower you to make informed decisions in perfecting your die casting process.

Die Cast Mold Types and Their Usage Frequency

Step-by-Step Guide to Designing Your Die Cast Mold

Designing a die cast mold involves a meticulous step-by-step process that can significantly impact the quality of your final product. The first step is to define the specifications of the casting, which includes determining the dimensions, weight, and desired surface finish. Once the specifications are established, you should create detailed designs using CAD software. This allows you to visualize the mold and make necessary adjustments before physical production begins. It is also essential to consider the material of the mold itself, as this will affect its durability and heat resistance during casting.

Next, focus on the cooling system within your mold design. An efficient cooling system is crucial for minimizing cycle times and enhancing the quality of the casted product. Incorporating cooling channels that follow the contours of the mold can help ensure uniform cooling, reducing warping and dimensional inaccuracies. Additionally, consider implementing features like ejector pins or lifters to facilitate the easy removal of the cast items post-casting. Each design decision plays a vital role in streamlining the casting process and producing high-quality die-cast parts that meet your project’s requirements.

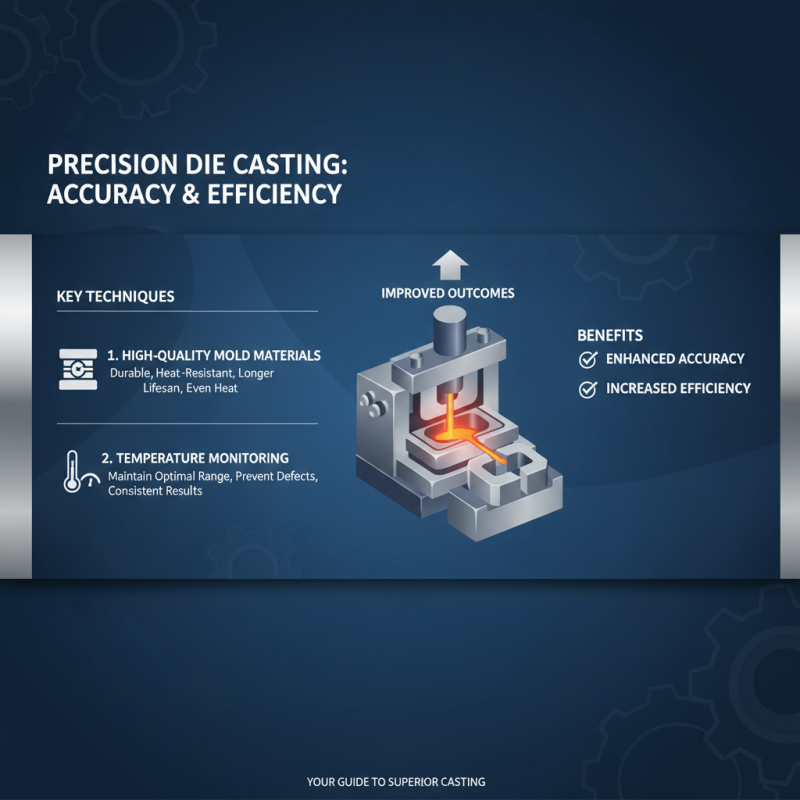

Key Techniques for Ensuring Accurate and Efficient Casting

When it comes to die casting, achieving accuracy and efficiency in your casting process is vital. One key technique is to invest in high-quality mold materials. Selecting durable and heat-resistant materials for your die cast molds not only enhances the lifespan of the molds but also ensures better heat distribution during the casting process, which leads to more consistent results. Always monitor the temperature and maintain it within optimal ranges to avoid defects in your final product.

Another essential tip is to optimize your design for the casting process. Complex shapes can pose challenges, so consider simplifying designs where possible. Incorporating features such as draft angles can help in the easy release of the casting from the mold, reducing wear and tear and ensuring cleaner casts. Additionally, using computer-aided design (CAD) software can help identify potential issues in the design stage, allowing for adjustments before the production process begins.

Finally, consistency in your casting parameters is crucial. Keep a close eye on variables such as pouring speed, pressure, and cooling time, as any fluctuations can lead to defects in your castings. Use data logging tools to record and analyze these parameters for continuous improvement. Regular maintenance of your molds and equipment will also contribute to the reliability of your casting process, ensuring efficient production runs and high-quality outputs.

Common Problems in Die Casting and How to Troubleshoot Them

Die casting is a precision manufacturing process that can sometimes encounter various challenges, impacting the final product quality. One common problem is the occurrence of air traps, where air gets trapped in the mold during filling, leading to incomplete castings. This can often be mitigated by optimizing the design of the mold and ensuring that venting systems are adequately implemented. Proper venting allows air to escape, ensuring a smoother fill and reducing the risk of defects.

Another prevalent issue in die casting is shrinking or warping of the final product. These defects typically arise when there is uneven cooling of the molten metal, often due to inadequate die temperature control. To address this, it is crucial to maintain consistent die temperatures throughout the cycle and consider the use of heat exchangers to manage cooling rates. Additionally, selecting the right alloy with suitable thermal properties can help minimize these risks and improve the overall quality and precision of the cast parts.

Related Posts

-

Top 5 Innovative Die Cast Equipment Examples Revolutionizing Manufacturing Efficiency

-

Ultimate Guide to Mastering Die Cast Tooling for Efficient Production

-

Ultimate Guide to Mastering Die Casting Techniques for Your Business Success

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

Best Die Cast Solutions: Enhancing Precision and Efficiency in Manufacturing

-

Unlocking Precision: The Science Behind Die Cast Tooling in Modern Manufacturing

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering