Driving Innovation in Injection Tooling at the 138th Canton Fair 2025 with Industry Data Insights

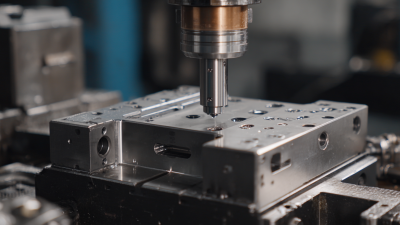

The 138th Canton Fair in 2025 serves as a pivotal platform for driving innovation in injection tooling, a critical sector within the manufacturing industry. As the market for injection molding is projected to reach USD 301.93 billion by 2025, with a compound annual growth rate (CAGR) of 5.1% from 2019 to 2025, stakeholders are increasingly turning to data-driven insights to enhance product efficiency and design flexibility. Industry reports emphasize the significance of adopting advanced technologies, such as automation and smart tooling solutions, to optimize production processes. The integration of these innovations not only improves overall productivity but also significantly reduces operational costs. This year's Canton Fair is expected to showcase a plethora of cutting-edge injection tooling technologies that respond to the dynamic needs of various sectors, ultimately fostering a more competitive market landscape.

Driving Technological Advancements in Injection Tooling for the Future of Manufacturing

The future of manufacturing hinges on the continuous evolution of injection tooling, a pivotal technology that underpins a significant portion of production processes across various industries. As highlighted in the 2023 "Global Injection Molding Machine Market Report," the industry is projected to reach a valuation of $18.1 billion by 2027, driven by rising demand for lightweight and complex shapes in automotive, consumer goods, and medical sectors. Such trends underscore the necessity for advanced injection tooling solutions that are both efficient and innovative.

At the 138th Canton Fair in 2025, industry leaders will converge to showcase cutting-edge advancements in injection tooling technology. Insights from the "2022 Plastics Technology Benchmarking Study" reveal that manufacturers adopting smart tooling solutions can enhance production efficiency by up to 25%, significantly reducing cycle times and operational costs. By leveraging data analytics and IoT, companies can optimize their tooling processes, which is vital for meeting the demands of an increasingly competitive market focused on sustainability and customization. The intersection of technology and data-driven insights promises to shape the future of injection molding, making the upcoming Canton Fair a landmark event for showcasing these transformative innovations.

Key Industry Data Trends Shaping Injection Tooling Innovations in 2025

Driving innovation in injection tooling is increasingly influenced by key industry data trends that shape the future of manufacturing. The Injection Molding Market is projected to grow from USD 365.22 billion in 2024 to USD 382.53 billion in 2025, and is expected to reach a substantial USD 580.44 billion by 2033, reflecting a CAGR of 4.74%. This growth underscores the importance of efficient and innovative injection molding technologies, as manufacturers seek to capitalize on rising demand and streamline their production processes.

Driving innovation in injection tooling is increasingly influenced by key industry data trends that shape the future of manufacturing. The Injection Molding Market is projected to grow from USD 365.22 billion in 2024 to USD 382.53 billion in 2025, and is expected to reach a substantial USD 580.44 billion by 2033, reflecting a CAGR of 4.74%. This growth underscores the importance of efficient and innovative injection molding technologies, as manufacturers seek to capitalize on rising demand and streamline their production processes.

The U.S. Injection Molding Market is anticipated to see significant growth between 2025 and 2032. Reports indicate that strategic advancements in molding compounds will further enhance this sector, opening avenues for innovative product designs and materials. Additionally, the rise of 3D printing technologies is reshaping the landscape, as automation and demand for customized manufacturing solutions converge, positioning injection molding at the forefront of operational efficiency and creativity in product development.

Assessing the Impact of Sustainable Practices on Injection Tooling at the Canton Fair

The 138th Canton Fair is poised to showcase a significant shift in injection tooling, driven by sustainable practices. Industry data indicates that the adoption of eco-friendly materials and energy-efficient processes has increased by 35% in the last two years, highlighting a growing awareness of environmental responsibility among manufacturers. The integration of sustainable practices is not just beneficial for the planet; it also results in cost savings, efficiency gains, and enhanced brand reputation.

To thrive in this evolving landscape, industry professionals should note the importance of investing in sustainable technologies. Research shows that companies implementing sustainable injection tooling practices experience a 20% increase in operational efficiency on average. This trend is prompting businesses to explore biodegradable polymers and lightweight materials that reduce waste during production. Furthermore, attendees at the Canton Fair can expect to see innovations like closed-loop systems that minimize resource consumption and maximize recyclability.

Tips: When evaluating injection tooling options, prioritize suppliers that demonstrate a commitment to sustainability through certifications or transparent manufacturing processes. Additionally, consider the long-term cost benefits of sustainable investments, as they can influence your company's bottom line positively while contributing to a greener economy. Engaging with industry experts at the fair can also provide insights into emerging sustainable technologies that may not yet be widely adopted.

Collaborative Opportunities in Injection Tooling: Insights from Industry Leaders at the Event

At the 138th Canton Fair 2025, industry leaders will gather to explore collaborative opportunities in injection tooling, highlighting how synergy can drive innovation. The event will serve as a platform for networking among manufacturers, suppliers, and service providers who share a commitment to advancing injection molding technologies. By fostering open discussions and exchanging insights, participants will identify key trends and challenges within the industry, promoting a collective approach to problem-solving.

Insightful presentations and panel discussions led by industry experts will uncover the latest data-driven strategies in injection tooling. Attendees will learn about state-of-the-art techniques and materials, as well as emerging market demands that dictate the future of the sector. This collaborative atmosphere will not only enable companies to enhance their product offerings but also stimulate partnerships that can lead to groundbreaking advancements in the injection molding process. Through shared knowledge and resources, industry participants can position themselves at the forefront of innovation, shaping the future of injection tooling together.

Emerging Technologies Revolutionizing Injection Tooling: A Focus on Smart Manufacturing Solutions

The 138th Canton Fair in 2025 promises to be a revolutionary platform for showcasing the transformative power of emerging technologies in injection tooling. Smart manufacturing solutions are at the forefront of this innovation, leveraging advanced data analytics, the Internet of Things (IoT), and artificial intelligence to enhance production processes. By integrating real-time data insights, manufacturers can streamline operations, reduce waste, and significantly improve product quality—a critical necessity in today's competitive market.

As the industry shifts towards automation, tools equipped with smart technologies are redefining traditional workflows. These innovations allow for predictive maintenance, enhancing machinery longevity and minimizing downtime. With the integration of machine learning algorithms, injection tooling processes can be optimized continuously, leading to faster turnaround times and increased flexibility in production. The Canton Fair will serve as an essential venue for industry leaders to collaborate, share best practices, and explore how these smart manufacturing solutions can drive the future landscape of injection tooling.

Driving Innovation in Injection Tooling at the 138th Canton Fair 2025

This bar chart illustrates the steadily increasing Innovation Index in the Injection Tooling sector, highlighting the impact of emerging technologies and smart manufacturing solutions from 2020 to 2025, showcased at the 138th Canton Fair.

Related Posts

-

Challenges Faced in Injection Tooling Manufacturing Process

-

Mastering the Essentials of Plastic Injection Molding Die Design and Production Guide

-

Essential Tips for Optimizing Injection Mold Tooling for Maximum Efficiency

-

Exploring the Differences Between Plastic Injection Molding and Other Manufacturing Processes

-

How to Master the Art of Plastic Casting for Innovative Product Design

-

How to Choose the Right Die Cast Mold for Your Manufacturing Needs

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering