10 Essential Tips for Mastering Plastic Injection Molding Processes

In the realm of manufacturing, mastery of the plastic injection molding process is critical for producing high-quality components efficiently. As industry expert Dr. Jennifer Lee aptly states, "Understanding the intricacies of plastic injection molding is not just about mastering the technology; it's about mastering the art of precision." This insight resonates deeply within the industry, emphasizing that both technical knowledge and practical experience are vital for success.

Plastic injection molding is a pivotal technique in fabricating intricate designs with durability and consistency. Challenges such as material selection, temperature control, and cycle time optimization often arise, making it essential for professionals to develop a comprehensive skill set. By applying the right strategies and understanding the nuances of the process, manufacturers can significantly enhance their output quality and operational efficiency.

This article presents ten essential tips designed to help practitioners navigate the complexities of plastic injection molding. Whether you are a seasoned expert or a newcomer to the field, these insights will provide valuable guidance for refining your processes and achieving mastery in the art of plastic injection.

Understanding the Basics of Plastic Injection Molding

Plastic injection molding is a widely used manufacturing process that enables the production of complex and precise plastic components. Understanding the basics of this process is crucial for anyone looking to optimize production efficiency and product quality. At its core, plastic injection molding involves melting plastic pellets, injecting the molten plastic into a mold, and allowing it to cool and solidify into the desired shape. According to industry reports, the global injection molding market is expected to reach approximately $471 billion by 2026, reflecting a robust annual growth rate driven by efficiencies in production and the increasing demand for plastic products across various sectors.

The success of plastic injection molding relies heavily on factors such as material selection, process parameters, and mold design. Selecting the right type of thermoplastic is vital, as it influences the mechanical properties and durability of the final product. Moreover, precise control over temperature and pressure during the injection process is essential to avoid defects like warping or air pockets. A 2021 study highlighted that optimal process control can reduce production costs by up to 30% while significantly improving product quality. As the industry evolves, embracing new technologies and innovations will further enhance the capabilities of plastic injection molding, making it a key driver in manufacturing sustainability and efficiency.

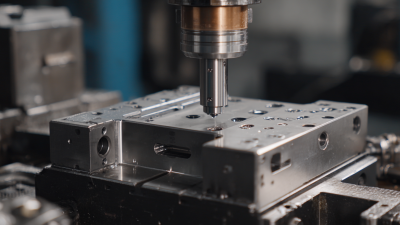

Key Equipment and Machinery in Injection Molding Processes

In the realm of plastic injection molding, selecting the right equipment and machinery is pivotal for achieving high-quality production. Essential machinery includes injection molding machines, molds, and auxiliary equipment such as chillers and conveyors. According to a 2022 industry report, the global injection molding market is projected to grow at a CAGR of 3.8%, underscoring the importance of efficient equipment choices to enhance productivity and reduce costs.

When choosing injection molding machines, it’s vital to consider their tonnage capacity, which directly affects the thickness and complexity of the parts being produced. Larger parts typically require machines with higher tonnage. Moreover, the advancement in nozzle technology, such as heated vs. non-heated nozzles, can significantly impact the consistency of the material flow and the overall quality of molded parts.

Tip: Always prioritize machine compatibility with your specific resin types, as this will optimize the melting and injection process, leading to superior end products. Additionally, investing in automation systems can increase efficiency—studies indicate that automated systems can reduce cycle times by up to 30%. In summary, understanding the key equipment in injection molding is crucial for optimizing production and maintaining competitive advantages in the market.

10 Essential Tips for Mastering Plastic Injection Molding Processes

Essential Materials Used in Plastic Injection Molding

When it comes to the plastic injection molding process, the selection of raw materials plays a vital role in determining the quality and performance of the final product. The two most commonly used types of plastics in this process are thermoplastics and thermosetting plastics.

Thermoplastics, such as polyethylene (PE) and polypropylene (PP), can be melted and reshaped multiple times, which makes them incredibly versatile for various applications. Their ability to be recycled adds an eco-friendly dimension, appealing to manufacturers aiming for sustainable production practices.

Thermosetting plastics, on the other hand, undergo a chemical change when they are heated, creating a rigid structure that cannot be remolded. Common examples include epoxy and phenolic resins. These materials are particularly suited for applications requiring high durability and heat resistance, making them ideal for automotive, electrical, and aerospace components. Understanding the distinct properties of these materials allows manufacturers to optimize their production processes and achieve desired mechanical and thermal characteristics in the end products.

Common Challenges and Solutions in Injection Molding

Injection molding is a complex process that often presents several challenges for manufacturers. One of the most common issues is inconsistent quality in the final product, which can stem from variations in the material properties or the molding conditions. To mitigate this, it is essential to establish a rigorous quality control system that monitors the input materials and adjusts the parameters of the molding process in real-time. Implementing advanced monitoring technologies can help identify deviations early, allowing for corrective actions to be taken before defects occur.

Another significant challenge in injection molding is cycle time optimization. Longer cycle times can lead to increased production costs and delays in delivery. Analyzing the cooling time, injection speed, and pressure can help identify bottlenecks in the process. Techniques such as numerical simulation can forecast potential issues and streamline the flow of materials, resulting in reduced cycle times. Additionally, investing in high-quality molds and ensuring they are well-maintained can drastically improve efficiency and product consistency, ultimately overcoming many of the typical setbacks faced in the injection molding industry.

10 Essential Tips for Mastering Plastic Injection Molding Processes - Common Challenges and Solutions in Injection Molding

| Tip Number | Tip | Common Challenges | Solutions |

|---|---|---|---|

| 1 | Understand Material Properties | Incorrect choice of material leading to defects. | Conduct thorough material testing and research. |

| 2 | Optimize Injection Speed | Inconsistent part quality. | Adjust speed settings based on part design and material. |

| 3 | Maintain Proper Temperature Control | Melting or cooling issues causing defects. | Utilize temperature control systems and sensors. |

| 4 | Design Efficient Mold Layout | Uneven filling and cooling. | Consult with mold design experts. |

| 5 | Implement Comprehensive Maintenance Schedules | Machine breakdowns and unexpected downtimes. | Establish a routine maintenance checklist. |

| 6 | Ensure Proper Venting | Gas traps leading to voids in parts. | Design molds to include sufficient venting features. |

| 7 | Monitor Cycle Times | Long cycle times reduce productivity. | Analyze and optimize cycle processes. |

| 8 | Select Appropriate Injection Pressure | Risk of damaging the mold or part. | Test different pressure settings to find the optimal range. |

| 9 | Check for Design Complexity | Difficulties in mold making for complex designs. | Simplify designs where feasible or consult experts. |

| 10 | Invest in Training and Skill Development | Lack of knowledgeable workforce can hinder production. | Provide regular training programs for staff. |

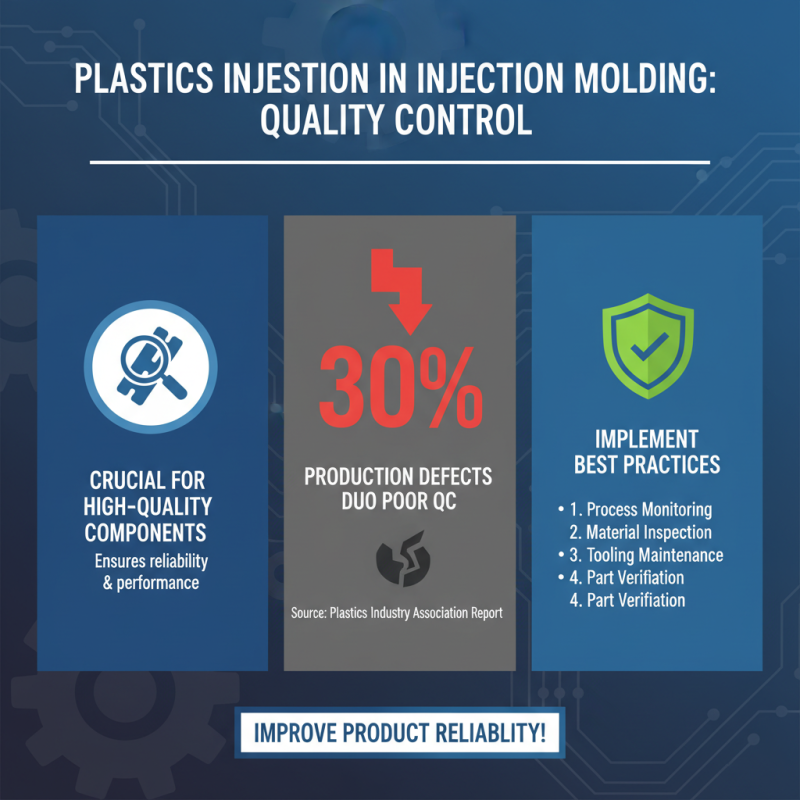

Best Practices for Quality Control in Injection Molding

Quality control in injection molding is crucial for ensuring the production of high-quality components. According to a recent report by the Plastics Industry Association, nearly 30% of production defects in injection molding result from improper quality control measures. Implementing best practices can mitigate risks and improve product reliability significantly.

One essential tip is to establish a robust monitoring system throughout the molding process. Utilizing advanced sensors and data analytics can help detect variations in temperature, pressure, and cycle times, which are vital for maintaining consistency. Regular calibration of machinery is also critical. A study by the American Society for Quality states that proper machine calibration can reduce defects by up to 25%, illustrating its importance in quality assurance.

Another effective practice involves thorough training for operators and staff. Ensuring that team members are well-versed in quality standards and molding techniques can lead to a significant reduction in errors. Implementing a continuous feedback loop allows employees to report issues promptly, facilitating quick resolutions. According to industry data, companies that emphasize employee training typically see a 15% decrease in defects and an increase in overall efficiency in their production lines.

Related Posts

-

Exploring the Differences Between Plastic Injection Molding and Other Manufacturing Processes

-

Exploring the Innovations in Plastic Injection Technology for a Sustainable Future

-

2025 Top 10 Innovations in Plastic Injection Molding You Can't Miss

-

Understanding the Future of Manufacturing: Innovations in Plastic Injection Tooling Technology

-

Challenges Faced in Injection Tooling Manufacturing Process

-

How to Master the Art of Plastic Casting for Innovative Product Design

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering