5 Essential Tips for Optimizing Die Cast Die Production Efficiency

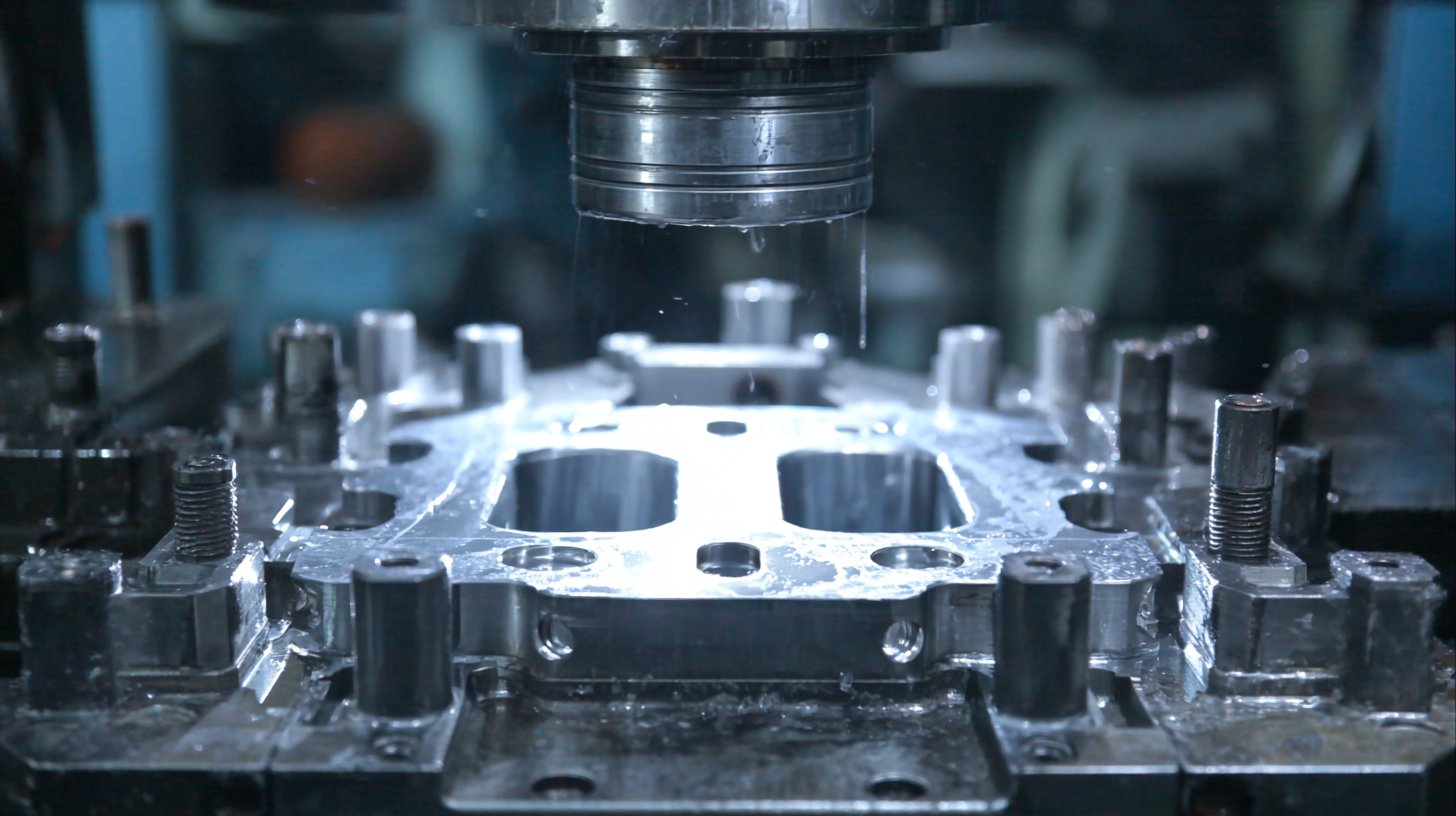

In the highly competitive landscape of manufacturing, optimizing production efficiency is crucial, especially in specialized processes like die casting. Die cast die production plays a pivotal role in determining the quality and cost-effectiveness of the final products. To ensure a smooth and efficient operation, it’s essential to adopt best practices that enhance productivity while minimizing waste and downtime.

This article presents five essential tips that focus on integrating digital solutions and best methodologies for optimizing die cast die production efficiency. By leveraging advanced technologies, improving process management, and refining design practices, manufacturers can significantly boost their operational capabilities.

This comprehensive guide will explore key strategies that not only streamline die cast die production but also contribute to overall industry advancement.

Identifying Key Factors That Affect Die Cast Die Production Efficiency

In the die casting industry, production efficiency is paramount to maintaining competitiveness and profitability. Key factors that influence this efficiency include the design of the die itself, the materials used, and the precision of the casting process. A well-designed die minimizes defects and reduces cycle times, while the choice of high-quality materials ensures durability and longevity, which can significantly decrease downtime for repairs or replacements.

Another critical factor is the temperature control during the casting process. Optimal thermal conditions can enhance fluidity and reduce cooling time, leading to faster production rates. Additionally, employing advanced technologies, such as automation and monitoring systems, can provide real-time data, enabling manufacturers to make informed adjustments to enhance production outcomes. By focusing on these key elements, companies can strategically improve their die cast die production efficiency, leading to better output and cost savings.

5 Essential Tips for Optimizing Die Cast Die Production Efficiency

| Factor | Description | Impact on Efficiency (%) | Best Practices |

|---|---|---|---|

| Material Quality | Utilizing high-quality materials enhances product integrity and reduces defects. | 20% | Source from reliable suppliers and conduct regular quality checks. |

| Die Maintenance | Regular maintenance of dies to ensure optimal performance and prevent downtime. | 25% | Implement a scheduled maintenance program and training for operators. |

| Process Temperature | Maintaining the correct temperature during production minimizes processing issues. | 15% | Use accurate thermocouples and adopt temperature monitoring systems. |

| Cycle Time | Reducing cycle time can significantly increase production output. | 30% | Analyze processes and identify bottlenecks to optimize workflow. |

| Operator Training | Well-trained operators can effectively manage machines and troubleshoot issues. | 10% | Regularly update training programs and include hands-on learning. |

Implementing Advanced Technologies for Enhanced Die Casting Processes

In die casting processes, implementing advanced technologies is crucial to enhance production efficiency. The integration of machine learning and phase-field simulations represents a significant leap forward. Data-driven approaches allow manufacturers to optimize the squeeze-casting process, demonstrating the effectiveness of analyzing ultra-small datasets. For instance, the recent optimization achieved for mine fuel tank partition castings highlighted that even with just 25 samples, significant improvements in quality and efficiency were realized.

To further capitalize on technological advancements, aluminum enterprises have started adopting graded procurement strategies. This method not only ensures the quality of cathode carbon blocks but also streamlines the sourcing process. By classifying their inputs into different grades, companies can make informed decisions that directly impact their production efficiency and end product quality. This systematic approach aligns with broader trends in manufacturing, where "thin and light" production technologies are gaining traction, ultimately contributing to more sustainable practices.

Tip 1: Invest in simulation software to allow engineers to visualize and predict outcomes before actual production, reducing waste and enhancing precision.

Tip 2: Embrace the concept of graded procurement to bolster supply chain management while ensuring optimal raw material quality.

By focusing on these strategies, manufacturers can not only enhance their production efficiency but also stay ahead in an increasingly competitive market.

Streamlining Workflow and Reducing Downtime in Die Production

To enhance die production efficiency, streamlining workflow is crucial. One effective approach is to implement a systematic layout for the production floor. By arranging workstations based on the die production flow, you can minimize unnecessary movements and time wastage. Each station should be equipped with the necessary tools and materials, readily accessible for workers. This organization not only boosts productivity but also fosters a safer work environment, reducing the likelihood of accidents related to a cluttered workspace.

Reducing downtime is another vital aspect of optimizing production. Regular maintenance schedules for machines help prevent unexpected breakdowns that can halt production. Employing predictive maintenance techniques, such as monitoring equipment performance through sensors, provides early warnings of potential issues before they escalate. Additionally, cross-training employees ensures that multiple team members can operate various machines. This flexibility allows for quick adjustments to the workforce, maintaining production flow even if some members are unavailable. By focusing on these strategies, die production can become more efficient and responsive to demand.

Production Efficiency in Die Casting

This chart illustrates the impact of various factors on die cast production efficiency, showcasing time spent on each phase of production.

Conducting Regular Maintenance to Preserve Die Integrity and Performance

Maintaining the integrity and performance of die-casting dies is crucial for optimizing production efficiency. Regular maintenance not only prolongs the lifespan of the dies but also ensures consistent quality in the final products. Establishing a routine inspection schedule allows for early detection of wear and tear, thus preventing unexpected downtime. During these inspections, it's essential to check for alignment issues and examine the surface for any signs of damage.

In addition to routine inspections, implementing a systematic cleaning process can significantly enhance die performance. Residues from previous castings can accumulate and affect the die's precision. Using appropriate cleaning agents can help remove these contaminants without harming the die material. Furthermore, consider lubricating moving parts regularly to reduce friction, which can lead to overheating and premature failure.

One of the most effective tips for optimizing die-cast die production efficiency is to document all maintenance activities. Keeping detailed records of inspections, repairs, and replacements helps identify patterns over time, allowing for proactive adjustments to be made. This strategy not only saves time but also ensures a systematic approach to die management, ultimately leading to improved production outcomes.

Training and Involving Staff for Continuous Improvement in Die Casting Operations

In the die casting industry, optimizing production efficiency is not solely reliant on advanced machinery but also hinges on the training and involvement of staff. Engaging employees in continuous improvement initiatives can lead to innovative solutions that enhance operations. By fostering a culture of open communication and collaboration, staff feel empowered to share ideas and identify areas for improvement.

In the die casting industry, optimizing production efficiency is not solely reliant on advanced machinery but also hinges on the training and involvement of staff. Engaging employees in continuous improvement initiatives can lead to innovative solutions that enhance operations. By fostering a culture of open communication and collaboration, staff feel empowered to share ideas and identify areas for improvement.

One essential tip is to implement regular training sessions that focus on the latest techniques and technologies in die casting. These sessions should not only cover operational processes but also emphasize problem-solving skills that encourage staff to take initiative. Additionally, consider creating cross-functional teams that bring together diverse expertise, allowing for a comprehensive approach to tackling production challenges.

Another key aspect is to involve employees in the development of workflow improvements. By seeking feedback and encouraging their participation in decision-making, you can harness their firsthand experience to streamline processes. This not only boosts morale but also leads to practical enhancements in die casting operations, ultimately resulting in improved efficiency and reduced cycle times.

Related Posts

-

The Future of Die Casting: Innovations Shaping Tomorrow's Manufacturing

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

Top 5 Innovative Die Cast Equipment Examples Revolutionizing Manufacturing Efficiency

-

Ultimate Guide to Mastering Die Cast Tooling for Efficient Production

-

Best Die Cast Solutions: Enhancing Precision and Efficiency in Manufacturing

-

Mastering the Essentials of Plastic Injection Molding Die Design and Production Guide

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering