The Future of Die Casting: Innovations Shaping Tomorrow's Manufacturing

As industries strive for greater efficiency and innovation, die casting emerges as a critical manufacturing process poised for transformation. The future of die cast technologies is illuminated by advancements in materials, automation, and design strategies that promise to enhance productivity and reduce production costs. With the continuous demand for lightweight and durable components across various sectors, including automotive, aerospace, and consumer goods, innovative approaches in die casting are redefining traditional boundaries.

From the integration of smart manufacturing systems to the exploration of sustainable materials, the evolution of die cast techniques is set to revolutionize how products are conceived and produced. This blog will delve into the latest innovations shaping tomorrow’s die casting landscape, offering insights into how these developments will influence the manufacturing processes of the future.

Emerging Technologies Revolutionizing Die Casting Processes

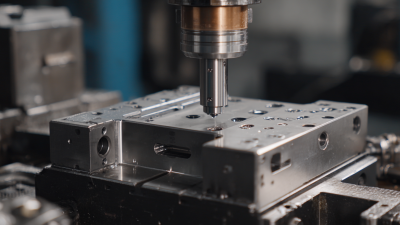

The die casting industry is witnessing a transformative shift driven by emerging technologies that are reshaping manufacturing processes. One of the most significant innovations is the integration of automation and robotics. Automated systems enhance precision and reduce cycle times, allowing manufacturers to produce complex shapes with minimal human intervention. This not only boosts efficiency but also increases safety, as machines take on the more hazardous components of the casting process.

In addition, advancements in materials science are paving the way for stronger and lighter alloys, optimizing product performance while lowering costs. Technologies such as 3D printing are also making waves by enabling rapid prototyping and customization, thus facilitating the production of intricate designs that were previously unthinkable. These innovations not only streamline die casting processes but also open up exciting new possibilities for industries ranging from automotive to aerospace, ultimately setting a new standard for quality and sustainability in manufacturing.

Sustainability Practices Transforming the Die Casting Industry

The die casting industry is undergoing a significant transformation, primarily driven by sustainability practices that aim to reduce environmental impact and enhance efficiency. According to a recent report by ResearchAndMarkets, the global die casting market is projected to reach USD 89.9 billion by 2026, with sustainability initiatives playing a pivotal role in this growth. Manufacturers are increasingly adopting eco-friendly materials and processes to meet the rising demand for greener products, reflecting a shift in consumer preferences towards environmentally responsible practices.

Innovations such as the implementation of closed-loop recycling systems have gained traction, allowing companies to recycle metal waste effectively. A study from the Aluminum Association indicates that recycling aluminum saves up to 95% of the energy required to create new aluminum from raw materials. Furthermore, advancements in energy-efficient technologies, such as electric die casting machines, have been shown to decrease production energy consumption by up to 30%. Such practices not only align with regulatory requirements but also enhance the overall sustainability of the die casting sector, making it more competitive in a rapidly evolving manufacturing landscape.

The Role of Automation and AI in Enhancing Efficiency

The manufacturing landscape is evolving rapidly, and die casting is no exception. The integration of automation and artificial intelligence (AI) is revolutionizing the efficiency of production processes, enabling manufacturers to achieve higher precision and reduced cycle times. Automated die casting machines can operate 24/7, minimizing downtime and enhancing productivity while maintaining consistent quality. With AI algorithms analyzing production data in real time, manufacturers can predict maintenance needs, optimize loading schedules, and fine-tune processes for maximum output.

Moreover, the role of AI extends beyond just efficiency; it enhances decision-making throughout the production chain. By leveraging machine learning, companies can gain insights into material behavior and casting technologies, allowing for smarter design choices that reduce waste and improve yield. This not only drives cost savings but also aligns with sustainability goals, a crucial aspect for future-forward manufacturers.

As the die casting industry embraces these innovations, the potential for streamlined operations and smarter manufacturing aligns perfectly with the demands of a competitive market.

Innovative Materials Driving the Future of Die Casting

The die casting industry is on the brink of transformation, driven by innovative materials that promise to redefine manufacturing processes. New alloys and composites are being developed that enhance strength and reduce weight, making them ideal for a variety of applications, from automotive to aerospace. These materials not only improve the performance of die-cast parts but also contribute to sustainability, as they often require less energy and raw material than traditional options.

Tips for manufacturers looking to embrace these innovations include investing in research and development to explore new material possibilities. Collaborating with material scientists can lead to unique solutions tailored to specific manufacturing challenges. Additionally, staying informed about industry trends and attending trade shows can provide insights into cutting-edge technologies that shape the future of die casting.

While the transition to these innovative materials may seem daunting, it offers the potential for significant competitive advantages. Companies should consider pilot projects to test new materials on a smaller scale before full implementation. This approach not only mitigates risks but can also yield valuable data on performance and customer preferences, paving the way for more informed decisions in the future.

Industry Trends: Adapting to Market Demands and Consumer Needs

As the die casting industry evolves, manufacturers are increasingly adapting to market demands and consumer needs. Recent data from the Grand View Research report indicates that the global die casting market size is expected to reach USD 30.3 billion by 2025, growing at a CAGR of 5.8%. This boom is driven not only by automotive applications but also by advancements in electronics and consumer goods, necessitating a more agile production approach. Companies are responding by implementing advanced technologies such as automation and AI, which enhance efficiency and precision, allowing for faster turnaround times and reduced waste.

Moreover, sustainability has become a pivotal concern. According to a study by MarketsandMarkets, the eco-friendly die casting market is projected to grow to USD 1.2 billion by 2024, highlighting a shift towards greener practices in manufacturing. Manufacturers are increasingly adopting recyclable materials and energy-efficient processes to meet consumer demand for sustainable products. As market trends shift, industries that harness these innovations while focusing on environmental responsibility are likely to thrive in the competitive landscape of tomorrow's manufacturing.

The Future of Die Casting: Innovations Shaping Tomorrow's Manufacturing - Industry Trends: Adapting to Market Demands and Consumer Needs

| Trend | Description | Impact on Industry | Adoption Rate |

|---|---|---|---|

| Automation in Die Casting | Increased use of robotics and AI for precision and efficiency. | Enhances productivity and reduces labor costs. | 70% |

| Sustainability Initiatives | Focus on eco-friendly materials and recycling processes. | Meets consumer demand for sustainable practices. | 60% |

| Advanced Alloys | Development of new alloys for higher strength and temperature resistance. | Improves product performance in demanding applications. | 50% |

| 3D Printing in Tooling | Utilization of 3D printing for developing die-casting tools. | Reduces lead times and enhances customization capabilities. | 40% |

| Industry 4.0 Integration | Smart manufacturing techniques for enhanced data analytics. | Optimizes operations and improves decision-making. | 30% |

Related Posts

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

Top 5 Innovative Die Cast Equipment Examples Revolutionizing Manufacturing Efficiency

-

Best Die Cast Solutions: Enhancing Precision and Efficiency in Manufacturing

-

Mastering the Essentials of Plastic Injection Molding Die Design and Production Guide

-

Challenges Faced in Injection Tooling Manufacturing Process

-

How to Choose the Right Die Cast Mold for Your Manufacturing Needs

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering