Exploring the Innovations in Plastic Injection Technology for a Sustainable Future

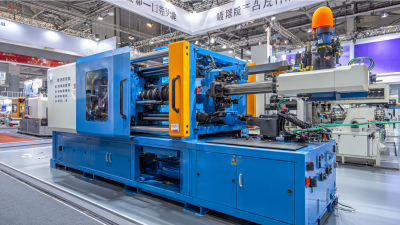

In recent years, the plastics industry has witnessed significant advancements in plastic injection technology, paving the way for a more sustainable future. As reported by the Global Plastics Alliance, approximately 360 million metric tons of plastic are produced annually, with injection molding accounting for nearly 30% of this production. These innovations not only enhance the efficiency and precision of the manufacturing processes but also address pressing environmental concerns. For instance, the adoption of bio-based resins and closed-loop systems in plastic injection is projected to reduce carbon emissions by up to 60% by 2030, according to the Ellen MacArthur Foundation. As companies increasingly prioritize sustainability, exploring these cutting-edge technologies will be essential for meeting both market demands and environmental regulations while ensuring the longevity of plastic injection's relevance in various industries.

Understanding the Basics of Plastic Injection Technology and Its Sustainable Potential

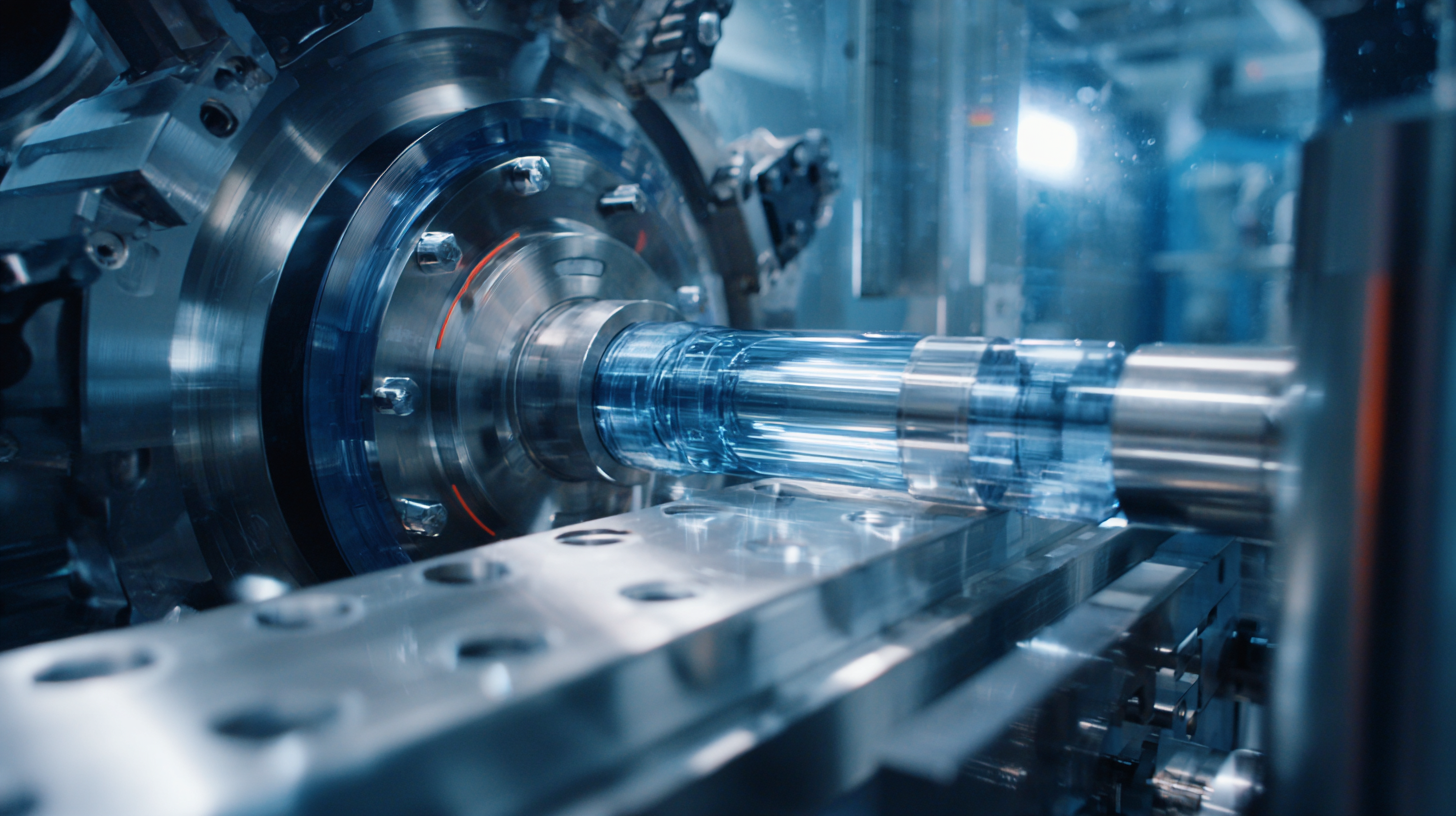

Plastic injection technology has become a pivotal manufacturing process, enabling the mass production of complex plastic components across various industries. At its core, this technology involves melting plastic pellets and injecting them into a mold, where they cool and solidify into the desired shape. However, with increasing environmental concerns, there's a pressing need to explore how this technology can evolve toward more sustainable practices.

Recent discussions around screw wear in injection molding highlight the importance of maintaining equipment for optimal performance and efficiency, which is critical for reducing waste and enhancing sustainability. Additionally, the recognition of innovative solutions through awards shows a growing commitment within the industry to prioritize sustainability. Manufacturers are also exploring eco-friendly substitutes for traditional plastics, which could significantly alter the landscape of injection molding, not only making it more environmentally friendly but also addressing issues such as weld lines that often compromise product integrity. This confluence of technology, innovation, and sustainability is essential for a greener future in plastic manufacturing.

Innovative Materials: Exploring Biodegradable Plastics for Injection Molding

The growing concern over plastic pollution has driven the industry to innovate with biodegradable plastics specifically designed for injection molding processes. These innovative materials not only aim to reduce the environmental impact associated with traditional plastics but also maintain the same functionality and versatility. Biodegradable plastics, derived from renewable resources like cornstarch or sugarcane, can decompose under specific conditions, offering a more sustainable alternative for various applications—from consumer goods to packaging.

Incorporating biodegradable plastics in injection molding presents unique challenges and opportunities. Manufacturers must adapt their existing technologies to accommodate the differing thermal properties and flow characteristics of these materials. However, advancements in polymer science have led to the development of compounds that perform efficiently in injection molding applications, making it easier for companies to transition towards more eco-friendly practices. As the demand for sustainable products continues to rise, the fusion of innovative materials and advanced injection technology holds promise for a greener future in manufacturing.

Innovations in Biodegradable Plastics for Injection Molding

This chart illustrates the growth in the use of various biodegradable plastics over recent years in injection molding applications. Data indicates a significant rise in the adoption of these materials, highlighting their potential for a sustainable future in manufacturing.

Energy-Efficient Practices: Reducing Carbon Footprint in Injection Processes

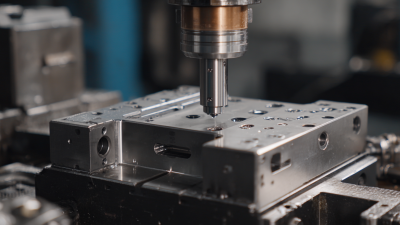

The evolution of plastic injection technology is increasingly reflecting a commitment to sustainability, particularly through energy-efficient practices that aim to reduce the carbon footprint during the injection process. Traditional injection molding methods often consume substantial energy, contributing to higher greenhouse gas emissions. However, recent innovations have paved the way for more sustainable alternatives. Manufacturers are now adopting advanced technologies such as servo-driven injection machines, which optimize energy usage by adjusting the power according to the specific needs of the injection cycle, resulting in significant energy savings.

Additionally, integrating renewable energy sources into the production process is gaining traction. Facilities are utilizing solar and wind energy to power their operations, minimizing reliance on fossil fuels. Coupled with advanced insulation techniques and optimized mold designs, these practices not only reduce energy consumption but also enhance overall production efficiency. By prioritizing sustainability in their operational frameworks, companies involved in plastic injection molding are making significant strides towards a greener future, showcasing how innovation can align with environmental stewardship.

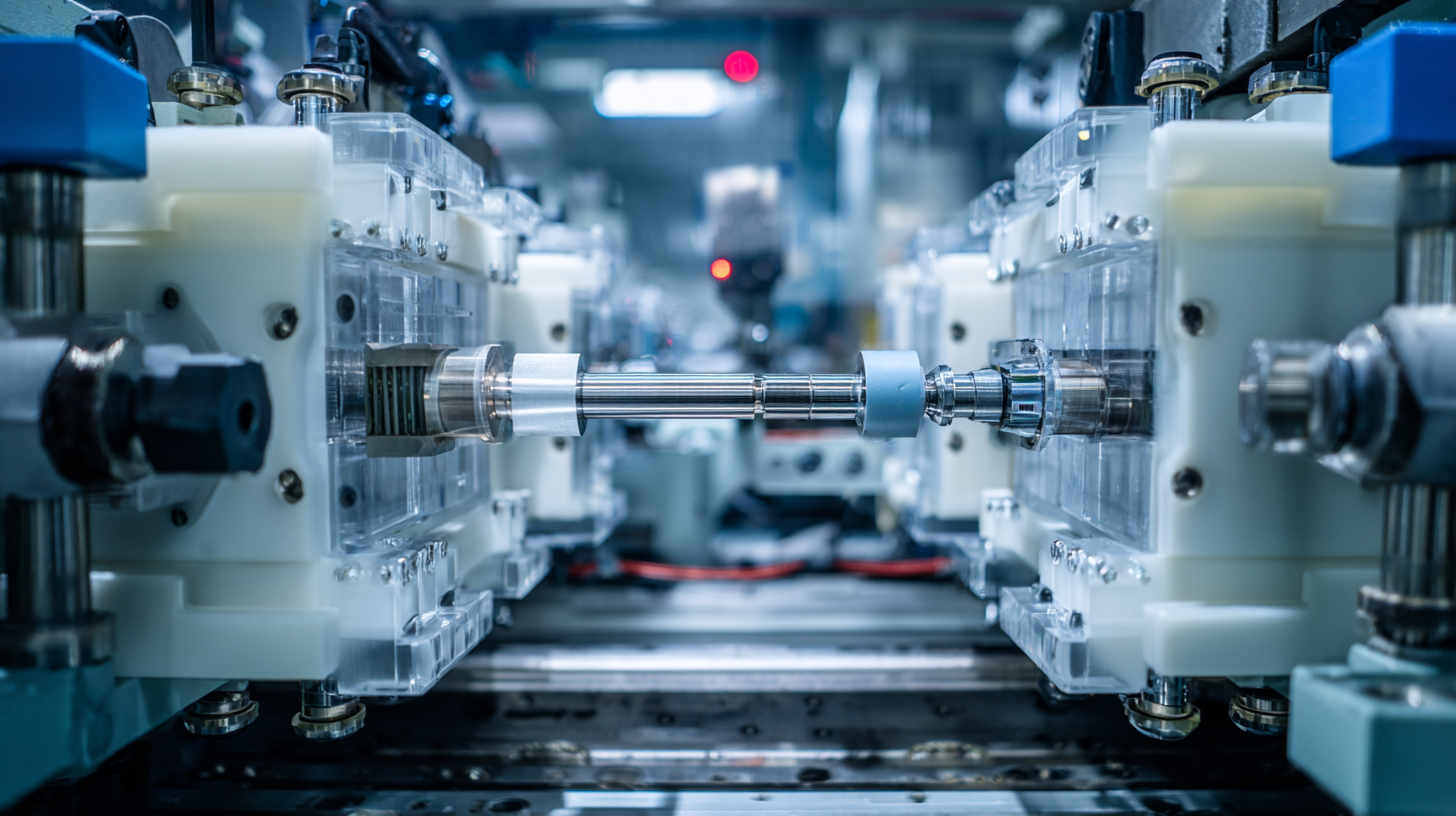

Integrating Smart Technology: The Role of AI and Automation in Injection Molding

The integration of AI and automation in plastic injection molding represents a pivotal shift towards enhancing efficiency and sustainability in manufacturing processes. As companies look to modernize their production lines, advanced technologies are being adopted to streamline operations and reduce waste. Recent developments in AI-driven systems, such as automated inspection and adaptive manufacturing processes, are enabling manufacturers to achieve precision and minimize error rates in mold design, thus enhancing overall productivity.

Moreover, the emergence of collaborative robots (cobots) highlights the growing trend of flexible manufacturing environments that can quickly adapt to changing demands. These robots work alongside human operators, learning from interactions to optimize workflows and improve output quality. With the plastic processing auxiliary equipment market projected to grow significantly, embracing smart technology in injection molding not only supports operational efficiency but also contributes to sustainable practices by reducing resource consumption and enhancing recycling efforts. As the industry continues to evolve, the role of AI and automation will be crucial in driving innovations towards a more sustainable future in plastic manufacturing.

Future Trends: Designing for Sustainability in Plastic Injection Manufacturing

The future of plastic injection manufacturing is increasingly intertwined with sustainability, as industries seek innovative solutions to reduce their environmental impact. One notable advancement comes from sustainable material suppliers who have developed bio-composite materials specifically for the automotive sector. These materials, made from recycled plastics, not only enhance the aesthetic quality of auto parts but also contribute to reducing waste by utilizing existing resources. This shift represents a crucial trend in designing for sustainability, showcasing how the injection molding process can evolve to incorporate eco-friendly materials while meeting consumer demands for high-performance products.

Moreover, the recent emphasis on smart technology integration into plastic injection molded items highlights another future trend. Innovations such as in-mold electronics pave the way for smarter surfaces in various applications, from automotive interiors to home appliances. These developments not only enhance functionality but also promote a circular economy by extending the lifecycle of products through intelligent design. As the industry moves forward, designing for sustainability will be paramount, driving the adoption of innovative materials and technologies that align with global ecological goals.

Exploring the Innovations in Plastic Injection Technology for a Sustainable Future - Future Trends: Designing for Sustainability in Plastic Injection Manufacturing

| Dimension | Value | Description |

|---|---|---|

| Recycled Material Usage | 30% | Percentage of recycled plastics used in production |

| Energy Consumption | 15% reduction | Decrease in energy use per unit produced |

| Biodegradable Plastics | 20% | Proportion of total materials that are biodegradable |

| Waste Reduction | 40% | Amount of production waste diverted from landfills |

| Sustainable Supplier Partnerships | 70% | Percentage of suppliers adhering to sustainability criteria |

| Customer Demand for Sustainable Products | 85% | Proportion of customers prioritizing sustainability in purchasing decisions |

Related Posts

-

Exploring the Differences Between Plastic Injection Molding and Other Manufacturing Processes

-

Challenges Faced in Injection Tooling Manufacturing Process

-

Driving Innovation in Injection Tooling at the 138th Canton Fair 2025 with Industry Data Insights

-

Understanding the Future of Manufacturing: Innovations in Plastic Injection Tooling Technology

-

Essential Tips for Optimizing Injection Mold Tooling for Maximum Efficiency

-

The Future of Die Casting: Innovations Shaping Tomorrow's Manufacturing

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering