Ultimate Guide to Mastering Die Casting Techniques for Your Business Success

In the competitive landscape of manufacturing, embracing advanced techniques like die casting can significantly enhance production efficiency and product quality. According to a report by MarketsandMarkets, the global die casting market is projected to grow from USD 58.14 billion in 2021 to USD 88.62 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth can be attributed to die casting's ability to produce complex shapes with high precision and minimal waste, making it an attractive solution for industries ranging from automotive to consumer electronics. As businesses strive for operational excellence, mastering die casting techniques becomes pivotal in ensuring not only immediate productivity gains but also long-term success in an ever-evolving market. Understanding the intricacies of this process will be essential for companies aiming to capitalize on its vast potential.

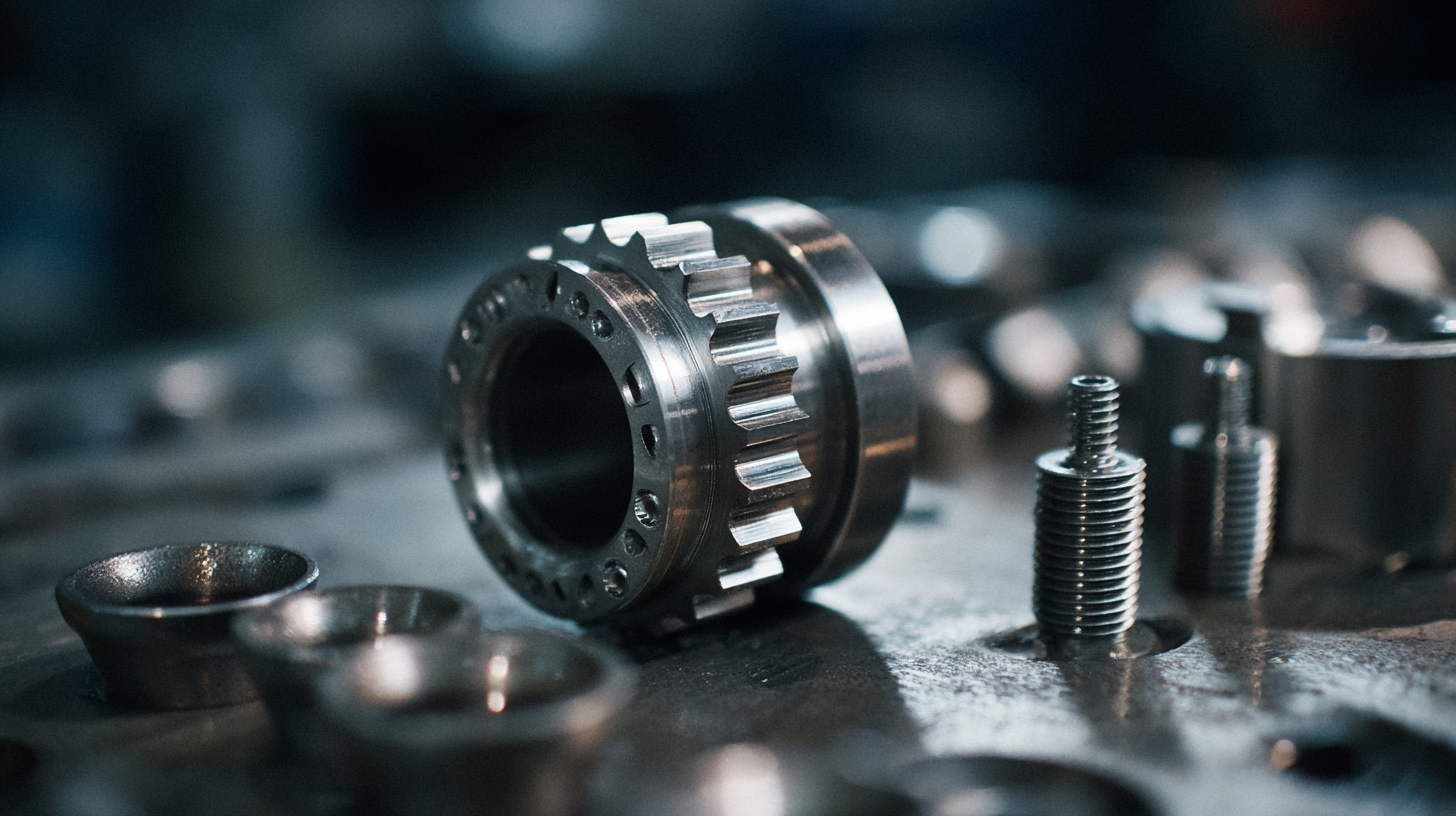

Understanding Die Casting: Key Techniques Every Business Should Know

Die casting is a crucial manufacturing process that offers precision and efficiency in producing complex metal parts. Understanding the key techniques involved in die casting is essential for businesses aiming to enhance their production capabilities. One of the primary techniques is gravity die casting, which utilizes gravitational force to fill the die with molten metal. This method is particularly suited for high-quality, low-volume production, providing excellent surface finishes and dimensional accuracy.

Another important technique is high-pressure die casting, where molten metal is injected into a mold at high pressure. This technique is ideal for mass production, allowing for the rapid creation of intricate components with minimal waste. Familiarity with this method can significantly increase a company’s output and profitability. Additionally, businesses should explore the intricacies of die design, cooling systems, and post-casting treatments, as these factors can profoundly impact the overall quality of the final product. Emphasizing these key techniques can lead to better decision-making and improved operational efficiency in the die casting process.

The Advantages of Die Casting: Why It's a Game Changer for Manufacturing

Die casting is rapidly becoming a game changer in the manufacturing landscape due to its impressive cost-efficiency and quality output. According to a report by Grand View Research, the global die casting market was valued at approximately $70 billion in 2020 and is expected to expand at a CAGR of 5.7% from 2021 to 2028. This growth is largely attributed to the increasing demand for lightweight and durable components in industries such as automotive, aerospace, and consumer electronics. With die casting, manufacturers can achieve precision and complex geometries that are often unattainable with traditional casting methods.

One of the standout advantages of die casting is its ability to produce components with a superior finish and tighter tolerances, which significantly reduces the need for extensive post-processing. A study from the American Foundry Society indicates that die casting can offer up to a 25% reduction in production costs compared to other metal forming processes. This efficiency not only accelerates production timelines but also allows for higher volume outputs, which aligns perfectly with the fast-paced demands of modern manufacturing. With these compelling benefits, incorporating die casting techniques can undoubtedly enhance operational success and competitiveness in the market.

Common Challenges in Die Casting and How to Overcome Them

Die casting is a widely utilized manufacturing process known for its precision and efficiency, but it is not without its challenges. One common issue faced by manufacturers is the problem of defects such as porosity, which occurs in 2-5% of die castings. To mitigate this, it's essential to maintain stringent quality control and regularly monitor the chemical composition of the alloys used. Utilizing advanced technologies like die temperature control can further enhance the quality, ensuring that defects are minimized and production costs are kept down.

Another significant challenge is the high initial tooling costs associated with die casting. According to a recent industry report, tooling can represent up to 40% of the total production cost in die casting processes. To overcome this barrier, businesses should consider strategies like implementing cost-sharing arrangements or investing in modular tooling that allows for flexibility and reuse across various projects.

**Tip:** Implementing robust simulation software can help predict challenges in the die casting process before actual production begins, potentially saving time and resources. Additionally, collaborating with experienced partners who understand these challenges can help streamline operations and enhance overall productivity.

Ultimate Guide to Mastering Die Casting Techniques for Your Business Success - Common Challenges in Die Casting and How to Overcome Them

| Challenge | Description | Solution | Impact on Production |

|---|---|---|---|

| Dimensional Accuracy | Inability to maintain specified tolerances can lead to expensive rework. | Implement strict monitoring of the tooling and regular calibration. | Reduces scrap rate and enhances product quality. |

| Surface Defects | Issues such as porosity or rough surfaces affect aesthetics and performance. | Optimize metal temperature and injection speed, and ensure clean dies. | Improves visual appeal and durability of products. |

| Tooling Issues | Frequent wear and tear can lead to increased downtime and maintenance costs. | Invest in high-quality materials and regular maintenance schedules. | Increases production efficiency and reduces operational costs. |

| Material Selection | Wrong choice can lead to performance failures or higher costs. | Conduct thorough material analysis and testing before production. | Optimizes performance and minimizes rejection rates. |

| Cost Management | Rising costs in materials and labor may squeeze margins. | Implement lean manufacturing practices to enhance efficiency. | Increases profitability and sustainability of operations. |

Top Tips for Optimizing Your Die Casting Processes for Efficiency

When aiming to optimize die casting processes for efficiency, one of the first steps is to assess the entire workflow for potential bottlenecks. Start by conducting a thorough analysis of your current operations, identifying areas where delays occur or resources are underutilized. Implementing lean manufacturing principles can significantly enhance efficiency—eliminate waste in each stage from design to production. Regularly training your team on these methodologies not only empowers them but ensures everyone is aligned with efficiency goals.

Another crucial tip is to invest in high-quality die casting machines and tools. The initial costs may be higher, but the benefits quickly outweigh the expenses through reduced maintenance and downtime. Incorporating automation wherever possible—from material handling to finishing processes—can streamline production and increase precision. Moreover, monitoring machine performance metrics can provide valuable insights, allowing for proactive adjustments that maximize output while maintaining quality. Together, these strategies create a robust framework for a more efficient and effective die casting operation.

Future Trends in Die Casting: What to Watch For in the Industry

As the die casting industry evolves, staying ahead of future trends is crucial for businesses aiming for long-term success. One significant trend shaping the future is the increasing adoption of automation and smart technology in the die casting process. With advancements in robotics and artificial intelligence, manufacturers can achieve greater precision and efficiency. Automated systems not only reduce labor costs but also minimize human error, leading to higher-quality products. Companies looking to remain competitive must invest in these technologies to streamline operations and enhance production capabilities.

Sustainability is another critical focus for the die casting industry moving forward. As environmental concerns grow, there is a strong push towards eco-friendly practices. By adopting sustainable materials and energy-efficient processes, businesses can not only meet regulatory requirements but also appeal to environmentally conscious consumers. Furthermore, innovations in recycling techniques for aluminum and other metals are becoming more popular, allowing manufacturers to reduce waste and lower their carbon footprint.

Embracing these sustainability trends will not only ensure compliance but also foster a positive brand image in an increasingly competitive marketplace.

Related Posts

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

Top 5 Innovative Die Cast Equipment Examples Revolutionizing Manufacturing Efficiency

-

10 Insights for Mastering Die Cast Plastic Techniques

-

Ultimate Guide to Mastering Die Cast Tooling for Efficient Production

-

Best Die Cast Solutions: Enhancing Precision and Efficiency in Manufacturing

-

The Future of Die Casting: Innovations Shaping Tomorrow's Manufacturing

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering