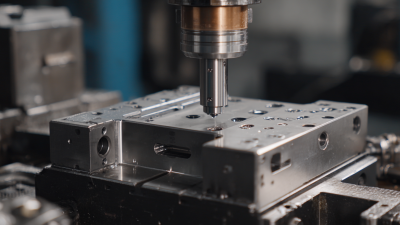

How to Optimize Your Die Mold Production Process for Maximum Efficiency

In the competitive landscape of manufacturing, optimizing the die mold production process is crucial for achieving maximum efficiency and minimizing costs. According to a report by Smithers Pira, the global market for injection molded products is projected to reach $305.3 billion by 2025, underlining the critical need for manufacturers to refine their production methods. Inefficiencies in die mold processes can lead to significant downtime and increased operational expenses, which, as per industry insights, can account for up to 30% of total production costs. As companies strive to enhance productivity while maintaining quality, a strategic approach to die mold production—incorporating advanced technologies, streamlined workflows, and continuous improvement practices—becomes more important than ever. This blog will explore key strategies and best practices that can be implemented to optimize die mold operations, ultimately positioning manufacturers for success in a rapidly evolving market.

Understanding the Importance of Process Optimization in Die Mold Production

In the highly competitive field of die mold production, process optimization emerges as a crucial element for ensuring both efficiency and precision. Understanding the workflows and identifying bottlenecks can significantly impact the overall production timeline and cost-effectiveness. By utilizing techniques such as lean manufacturing and continuous improvement, companies can minimize waste and enhance their operational capacity. This approach not only accelerates the production cycle but also ensures that high-quality molds are produced consistently, meeting the rigorous demands of the market.

Moreover, investing in advanced technologies such as automation and data analytics plays a pivotal role in streamlining processes. These tools provide valuable insights into production metrics, allowing for real-time adjustments and predictive maintenance. As a result, manufacturers can achieve a balance between speed and quality, ultimately leading to a more robust bottom line. Emphasizing the importance of process optimization in die mold production not only fosters innovation but also enhances customer satisfaction by delivering superior products in a timely manner.

Identifying Bottlenecks: Key Areas to Enhance Efficiency in Your Workflow

Identifying bottlenecks in the die mold production process is crucial for enhancing efficiency and ensuring competitive advantage. According to a report from the American Society for Quality, as much as 30% of a production team’s time can be wasted due to delays and inefficiencies in workflow. Addressing these bottlenecks not only improves output but also reduces operational costs significantly. Key areas to examine include part design, tool setup times, and machine maintenance schedules. Implementing robust tracking systems can help identify where time is lost and guide the necessary adjustments.

One of the most impactful strategies for optimizing workflow is the adoption of lean manufacturing principles. A study by the Lean Enterprise Institute highlighted that companies that embrace lean methodologies can reduce lead times by up to 50%, directly addressing inefficiencies. Furthermore, introducing advanced technologies such as real-time data analytics and automation can streamline processes and provide valuable insights into production capabilities. By targeting these critical areas for improvement, businesses can enhance their die mold production process, leading to increased productivity and a stronger position in the market.

| Bottleneck Area | Identified Issues | Suggested Enhancements | Expected Efficiency Gain (%) |

|---|---|---|---|

| Material Preparation | Inconsistent material quality | Implement quality control checks | 15% |

| Machining Operations | Long setup times | Adopt modular tooling | 20% |

| Quality Inspection | Lack of automated inspection | Integrate automated measuring systems | 25% |

| Assembly Line | Frequent operator errors | Enhance training and process standardization | 18% |

| Logistics | Inadequate inventory management | Implement inventory tracking software | 12% |

Leveraging Technology: Tools and Software for Streamlining Production

In the ever-evolving landscape of die mold production, leveraging technology is essential for enhancing efficiency and reducing operational costs. Recent industry reports indicate that 70% of manufacturers who adopt advanced software tools experience a significant decrease in production times, often by up to 30%. The integration of CAD/CAM software allows for precise modeling and machining, minimizing errors and improving the overall quality of the molds produced.

Tip: Invest in robust simulation software to analyze the mold design before production. This can help in identifying potential issues early on, saving both time and resources.

Additionally, automation technologies, including robotics and IoT-enabled machines, can markedly streamline the production process. According to a study from the National Association of Manufacturers, companies implementing smart manufacturing technologies report a 50% increase in output capacity. These tools help in real-time monitoring and data analytics, allowing for better decision-making and reduced downtime.

Tip: Consider utilizing cloud-based systems for better collaboration among teams. This improves communication and ensures that everyone is on the same page regarding projects and deadlines.

Implementing Lean Manufacturing Principles in Die Mold Production

Implementing lean manufacturing principles in die mold production can lead to significant improvements in efficiency and waste reduction. Lean manufacturing focuses on maximizing value by minimizing waste, which is vital in an industry where precision and timeliness are critical. To start, companies can conduct a thorough analysis of their production flow, identifying bottlenecks and non-value-adding activities. By streamlining these processes, such as optimizing the setup time and reducing cycle times, manufacturers can enhance their production rate while maintaining the quality of their molds.

Another essential aspect of lean manufacturing is fostering a culture of continuous improvement. Engaging employees at all levels to provide feedback and suggest improvements can lead to innovative solutions that enhance productivity. Techniques such as 5S (Sort, Set in order, Shine, Standardize, Sustain) can create an organized and efficient workspace, while tools like value stream mapping can help visualize and improve the workflow. As die mold producers embrace these lean principles, they not only reduce costs but also enhance their ability to respond to market demands quickly, giving them a competitive edge in a fast-paced industry.

Die Mold Production Efficiency Metrics

This bar chart illustrates key metrics for optimizing die mold production efficiency. Shorter cycle times and setup times paired with lower scrap rates lead to higher production output, ensuring maximum efficiency in the manufacturing process.

Training and Empowering Your Team for Continuous Improvement in Processes

Empowering your team is crucial for optimizing die mold production processes. The backbone of any successful operation lies in its workforce; investing in their training not only enhances their skill sets but also fosters a culture of innovation. By regularly updating your team's knowledge on the latest technologies and techniques in die mold manufacturing, you ensure that they are equipped to identify inefficiencies and suggest improvements.

Creating avenues for continuous improvement also involves encouraging collaboration and open communication within your team. Implementing regular feedback loops allows team members to share insights and brainstorm solutions collectively. Recognizing and rewarding contributions can inspire a proactive approach to problem-solving and drive your team to seek innovative ways to enhance productivity. Ultimately, a well-trained and empowered workforce is the key to achieving maximum efficiency in die mold production, making your operations more adaptive and resilient to changes in demand.

Related Posts

-

How to Choose the Right Die Cast Mold for Your Manufacturing Needs

-

Exploring the Differences Between Plastic Injection Molding and Other Manufacturing Processes

-

Challenges Faced in Injection Tooling Manufacturing Process

-

Essential Tips for Optimizing Injection Mold Tooling for Maximum Efficiency

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

-

Mastering the Essentials of Plastic Injection Molding Die Design and Production Guide

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering