2025 Top 5 Trends in Injection Mold Technology You Need to Know

As we approach 2025, the injection mold industry is on the cusp of significant transformation driven by technological advancements and evolving market demands. Industry reports suggest that the global injection molding market is expected to reach a staggering USD 300 billion by 2027, highlighting a compound annual growth rate (CAGR) of 5.3% from 2020 to 2027. This growth is propelled by increasing applications across sectors such as automotive, consumer goods, and healthcare, all of which are striving for enhanced efficiency and sustainability in their manufacturing processes.

Expert insights from Dr. Emily Chan, a prominent figure in the field of injection mold technology, underline the importance of staying ahead of these trends. Dr. Chan states, "The future of injection molding lies in our ability to integrate smart manufacturing practices and sustainable materials into our processes." As we delve into the top five trends that are expected to shape the landscape of injection mold technology in 2025, it becomes increasingly clear that innovations such as advanced materials, automation, and digital twin technology will play pivotal roles in redefining efficiency, cost-effectiveness, and environmental responsibility within the industry. These developments not only promise to enhance production capabilities but also aim to meet the rising consumer demand for environmentally friendly solutions.

Emerging Materials Transforming Injection Mold Design in 2025

In 2025, the injection mold technology landscape is poised for remarkable advancements, primarily driven by the emergence of innovative materials. These new materials are not only enhancing the efficiency and versatility of mold designs but are also opening doors to unprecedented applications across various industries. From biopolymers to advanced composites, the focus is shifting toward sustainable and lightweight solutions that promise improved performance and reduced environmental impact.

One of the key trends is the adoption of thermoplastic elastomers (TPEs), which offer a unique combination of flexibility and durability. These materials enable the creation of molds that can withstand higher temperatures and pressures, thus expanding their usability in demanding environments. Additionally, advancements in nanomaterials are enabling manufacturers to produce molds with enhanced strength and reduced weight, facilitating faster production cycles and lower energy consumption. As industries continue to evolve, the integration of these emerging materials into injection mold design will undoubtedly redefine standards and push the boundaries of what is possible in manufacturing.

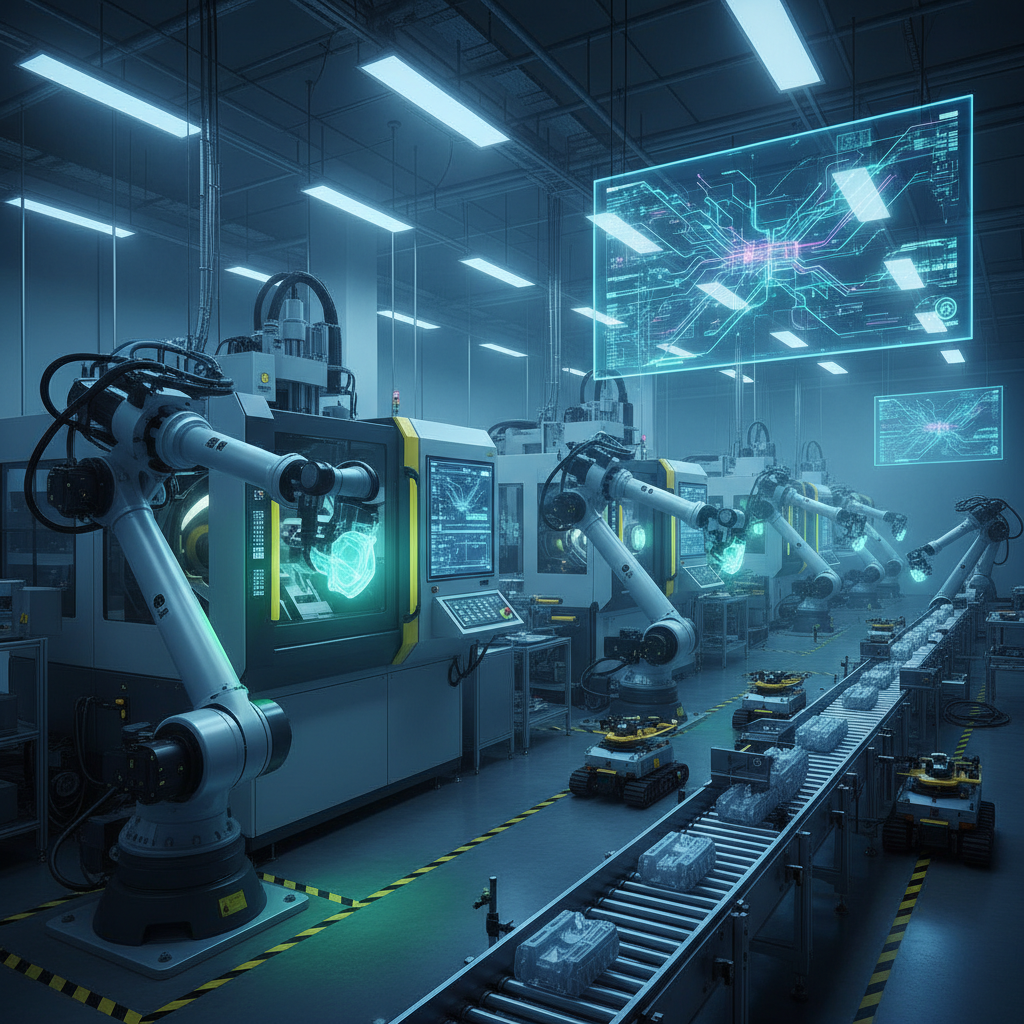

Smart Manufacturing: The Role of AI and Automation in Injection Molding

As the landscape of injection molding evolves, the integration of AI and automation emerges as a pivotal trend reshaping the industry. Smart manufacturing harnesses advanced algorithms and robotics to streamline production processes, resulting in higher efficiency and reduced waste. By implementing AI-driven predictive maintenance, manufacturers can anticipate potential machine failures before they occur, minimizing downtime and optimizing productivity.

Tips: To effectively integrate AI in your injection molding operations, begin by assessing your current processes to identify areas that would benefit most from automation. Invest in training for your workforce to ensure they are skilled in both traditional manufacturing techniques and modern technological applications. Collaborating with technology providers can also facilitate a smoother transition into smart manufacturing.

Additionally, data analytics plays a crucial role in refining production techniques. By analyzing real-time data from the manufacturing line, companies can make informed decisions that enhance quality control and reduce material costs. Embracing these technologies not only fosters innovation but also positions companies competitively within the injection molding market.

Tips: Regularly review and update your data analytics software to ensure you’re leveraging the latest advancements. Setting up cross-functional teams can also help bridge the gap between engineering, production, and IT, ensuring a cohesive approach to implementing smart manufacturing technologies.

Sustainability in Injection Molding: Eco-Friendly Practices for 2025

Sustainability is set to be a pivotal focus in injection molding technology by 2025. As environmental concerns escalate, the industry is increasingly adopting eco-friendly practices. According to a recent report by the Association for Manufacturing Excellence, about 70% of manufacturers plan to invest in sustainable technologies over the next three years. This commitment includes the utilization of biodegradable materials and energy-efficient production processes that significantly reduce carbon footprints.

One innovative approach gaining traction is the use of recycled materials in injection molding. The Global Recycling Foundation estimates that incorporating recycled content can reduce energy consumption by up to 40%. Additionally, advances in process optimization, such as utilizing cold runners and reducing cycle times, are also on the rise. These methods not only lower material waste but also enhance overall production efficiency. Overall, the trend towards sustainability in injection molding is not just an ethical imperative but a strategic opportunity for manufacturers aiming to lead in the competitive landscape of 2025.

2025 Innovations in Injection Mold Technology: Eco-Friendly Practices

This chart illustrates the top eco-friendly practices in injection mold technology projected for 2025, highlighting their anticipated adoption rates among manufacturers.

Advancements in Mold Maintenance Technologies for Improved Efficiency

The advancements in mold maintenance technologies are set to revolutionize the injection molding industry by enhancing efficiency and reducing downtime. One significant trend is the implementation of predictive maintenance techniques powered by IoT devices and advanced analytics. These systems enable manufacturers to monitor the condition of molds in real-time, allowing for early detection of potential issues before they escalate into costly repairs. This proactive approach minimizes unplanned downtime, leading to smoother production processes and increased output.

In addition to predictive maintenance, automated cleaning and servicing technologies are emerging as key advancements in mold maintenance. Automated systems that utilize robotics and smart cleaning solutions streamline the maintenance process, ensure thorough cleaning of molds, and enhance overall mold longevity. These innovations not only save time but also significantly reduce labor costs associated with manual cleaning. As companies continue to invest in these cutting-edge technologies, the focus on efficiency and productivity in injection mold technology is expected to grow, paving the way for more sustainable manufacturing practices.

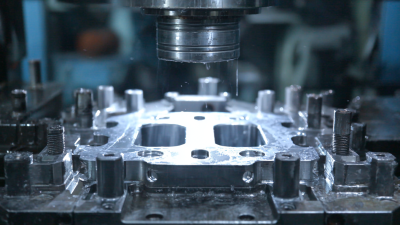

Precision Engineering: The Impact of 3D Printing on Injection Mold Fabrication

The integration of 3D printing into injection mold fabrication is revolutionizing the industry, offering unprecedented levels of precision and customization. Traditional mold-making processes can be time-consuming and costly, often requiring lengthy lead times and significant manual labor. However, 3D printing enables manufacturers to create intricate mold designs with complex geometries that were previously unattainable. By utilizing advanced materials and additive manufacturing techniques, mold designers can push the boundaries of creativity while ensuring that molds are produced with high accuracy and reduced waste.

Additionally, the impact of 3D printing on injection mold technology extends to rapid prototyping. Designers can create and iterate on mold designs quickly, testing them for fit and functionality before committing to costly production runs. This flexibility not only accelerates the development cycle but also allows for more innovative designs that can enhance performance and efficiency in the molding process. As companies continue to explore these technological advancements, the synergy between 3D printing and injection molding is likely to set the stage for a new era of manufacturing, characterized by enhanced precision engineering and streamlined production workflows.

2025 Top 5 Trends in Injection Mold Technology You Need to Know

| Trend | Description | Impact on Industry | Future Prospects |

|---|---|---|---|

| Incorporation of 3D Printing | Utilization of 3D printing to create complex mold designs that were previously unattainable. | Reduces lead times and allows for rapid prototyping. | Expected to become a standard practice by 2025. |

| Sustainability in Materials | Shift towards biodegradable and recyclable materials in injection molding processes. | Lowers environmental impact and meets consumer demand for sustainable products. | Growing trend with major adoption expected by 2025. |

| Smart Molding Technology | Integration of IoT devices for real-time monitoring and data analysis during the molding process. | Enhances quality control and optimizes production efficiency. | Expected widespread adoption to reduce operational costs. |

| Advanced Mold Cooling Techniques | Implementation of innovative cooling methods to reduce cycle times. | Improves productivity and part quality. | Anticipated to become a key factor in competitive manufacturing. |

| Simulation-Driven Design | Using advanced simulation software to predict outcomes and optimize mold designs before production. | Reduces trial-and-error phases, saving time and materials. | Will likely streamline the design process significantly. |

Related Posts

-

Mastering the Essentials of Plastic Injection Molding Die Design and Production Guide

-

How to Choose the Right Die Cast Process for Your Next Project

-

The Future of Die Casting: Innovations Shaping Tomorrow's Manufacturing

-

How to Optimize Your Die Mold Production Process for Maximum Efficiency

-

Essential Tips for Optimizing Injection Mold Tooling for Maximum Efficiency

-

5 Essential Tips for Optimizing Die Cast Die Production Efficiency

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering