Unlocking Efficiency: How Innovations in Die Mold Technology Are Shaping the Future of Manufacturing

In the rapidly evolving landscape of manufacturing, innovations in die mold technology stand at the forefront, driving unprecedented efficiency and precision across various industries. As the demand for high-quality, cost-effective production methods intensifies, manufacturers are increasingly turning to advanced die mold solutions to streamline their processes and enhance their competitive edge. This transformation not only redefines traditional manufacturing practices but also introduces a myriad of digital advancements that facilitate greater customization and responsiveness to market needs.

By harnessing the potential of cutting-edge technologies such as 3D printing, automation, and smart data analytics, die mold innovations are poised to unlock new levels of productivity and sustainability. As we delve into the intricacies of this technological revolution, it becomes evident that the future of manufacturing will be heavily influenced by the continuous evolution of die mold technology, paving the way for a more efficient and resilient industry.

The Evolution of Die Mold Technology in Manufacturing

The evolution of die mold technology has significantly transformed the manufacturing landscape over the past few decades. According to a recent report by MarketsandMarkets, the global die casting market is projected to reach USD 84.62 billion by 2026, growing at a CAGR of 6.09% from 2021. This growth is primarily driven by advancements in die mold materials and manufacturing processes, which have led to increased precision and efficiency.

Innovations such as 3D printing and simulation software are revolutionizing the design and production of molds. By utilizing 3D printing technologies, manufacturers can produce complex die molds quickly and cost-effectively, reducing lead times from months to just a few weeks. Furthermore, the integration of simulation software allows for real-time testing and optimization of mold designs, resulting in higher quality end products with fewer defects. A report by Technavio highlights that 20% of manufacturers have already adopted such technologies, underscoring a shift towards more agile and responsive manufacturing practices.

As die mold technology continues to evolve, its impact on productivity and sustainability will only intensify. With the ability to manufacture molds that are both lightweight and robust using advanced materials, manufacturers can significantly reduce energy consumption and waste. This not only enhances operational efficiency but also aligns with the growing demand for sustainable manufacturing solutions, reflecting a broader industry trend towards innovation-driven growth.

Key Innovations Driving Efficiency in Die Mold Production

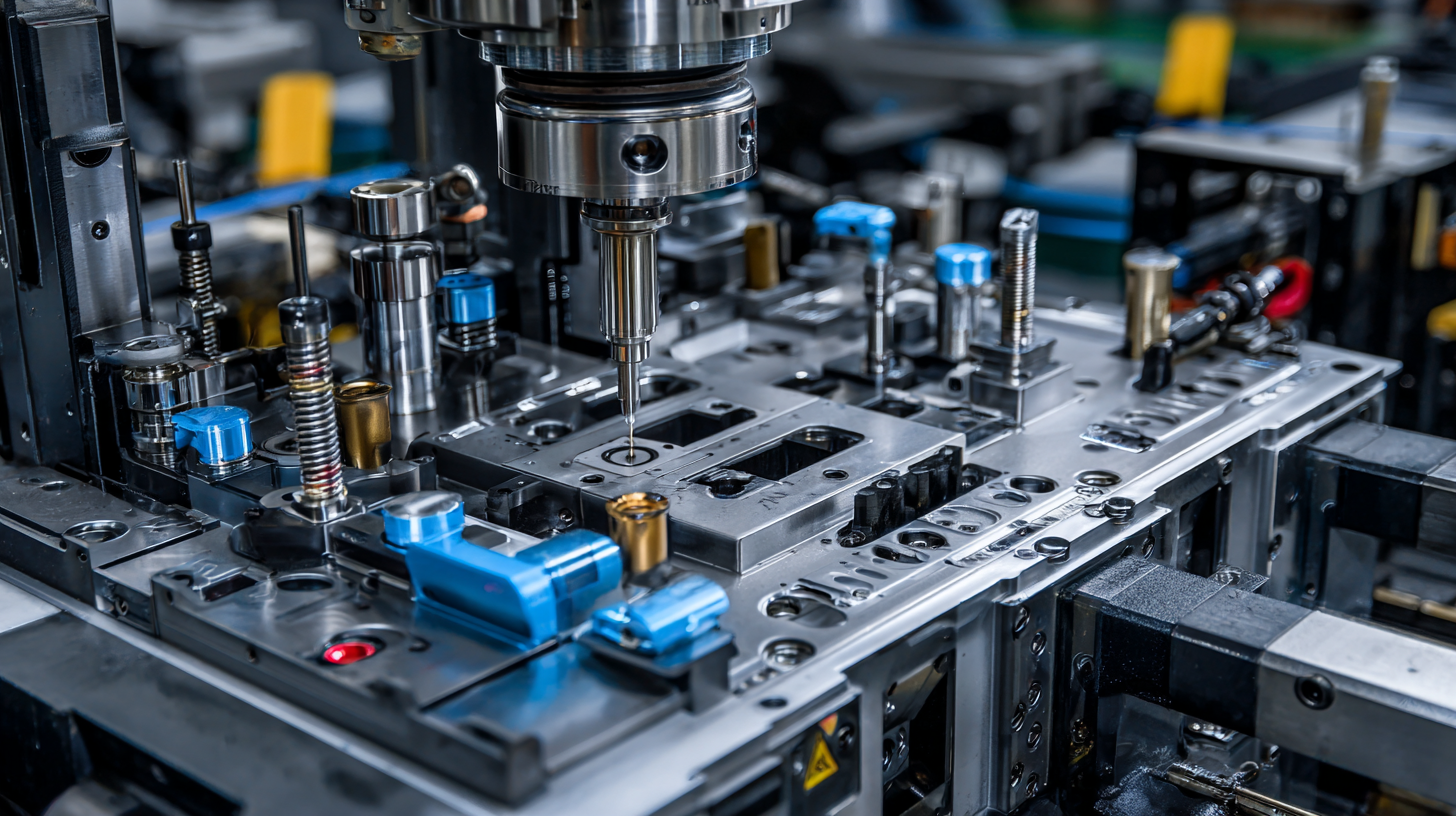

In the ever-evolving landscape of manufacturing, die mold technology is experiencing a notable transformation that heralds increased efficiency and productivity. Key innovations such as additive manufacturing and advanced simulation software are at the forefront of this change. According to a report by MarketsandMarkets, the global die and mold market is expected to reach $105.9 billion by 2025, growing at a CAGR of 5.1%. This growth is powered by the increasing demand for precision and faster production cycles across various sectors, including automotive and consumer goods.

One significant innovation is the integration of 3D printing technologies in mold production. This allows for rapid prototyping and reduces lead times significantly. Companies can create complex geometries that were previously impossible with traditional machining methods, enhancing both design flexibility and material efficiency. Furthermore, the use of simulation software enables manufacturers to optimize mold designs before production, minimizing errors and material waste.

Tips: When considering enhancements in die mold technology, invest in training for your team to stay updated on the latest software tools. Additionally, collaborating with suppliers who specialize in advanced technologies can provide insights that lead to optimized production processes. Embracing these innovations can not only streamline operations but also position your business at the forefront of industry advancements.

The Impact of Advanced Materials on Die Mold Performance

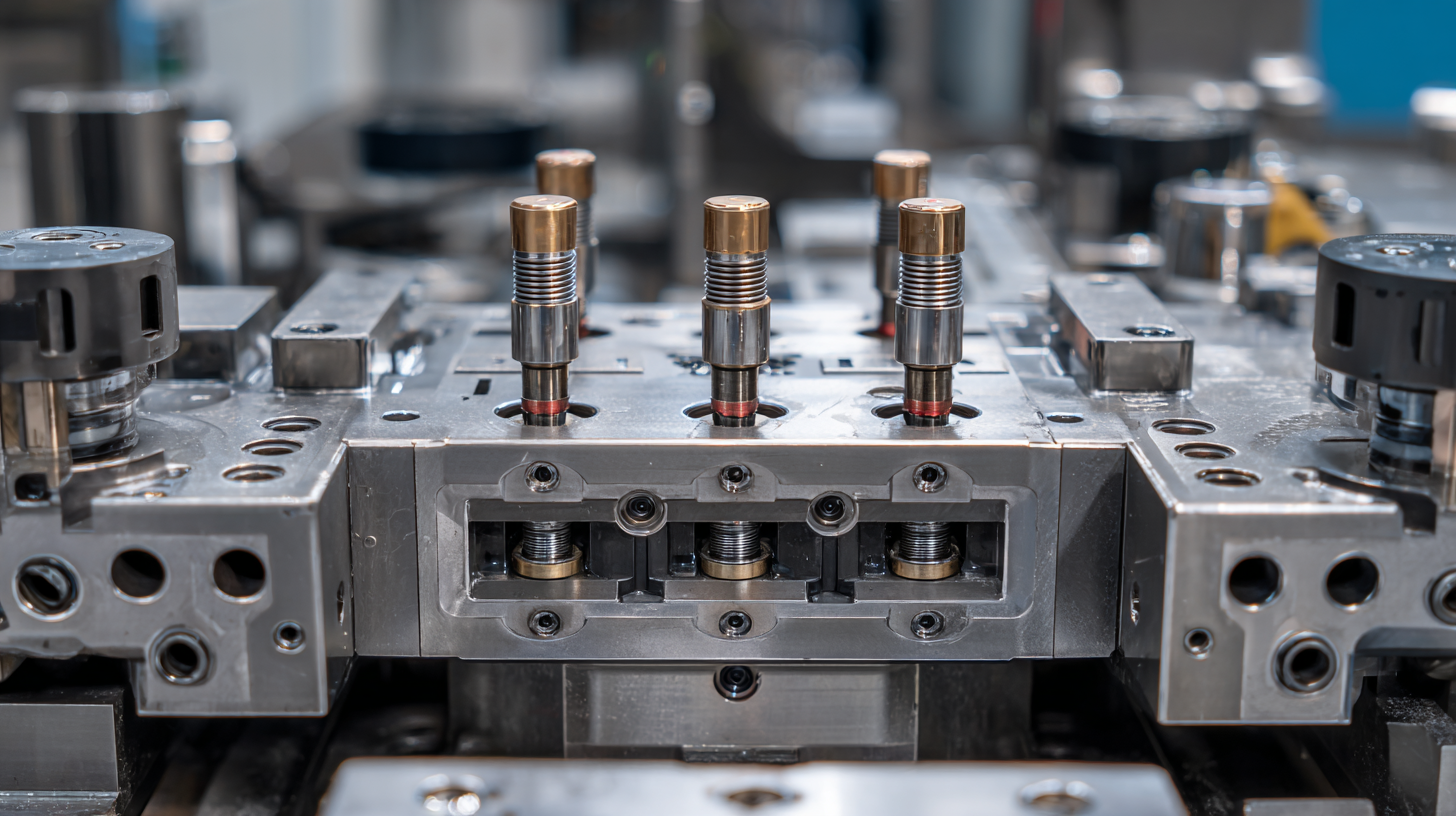

The evolution of die mold technology is significantly influenced by advancements in materials science. The integration of sophisticated materials, such as glass fiber reinforced polymers (GFRP) and new composite blends, is redefining mold performance. Recent studies have highlighted the robust characteristics and multistability afforded by innovative metamaterials like the Möbius strip structure, showcasing how these materials can enhance mold designs for precision applications. These developments not only improve production efficiency but also broaden the scope of design possibilities within manufacturing.

**Tip: Consider using advanced composite materials in your mold designs to enhance durability and performance.** Additionally, the mold-glass interface adhesion mechanisms found in precision glass molding reveal that material selection and surface wettability are critical factors in optimizing mold performance. By leveraging these insights, manufacturers can significantly reduce defects and increase throughput.

**Tip: Focus on surface treatment processes to enhance adhesion properties and ensure superior molding quality.** As the industry moves towards more complex designs, such as in-mold electronics and next-gen semiconductor packaging, the importance of co-designing with advanced materials cannot be overstated. These strategies facilitate the development of efficient, high-performance products, driving the future of manufacturing into a new era.

Unlocking Efficiency: How Innovations in Die Mold Technology Are Shaping the Future of Manufacturing - The Impact of Advanced Materials on Die Mold Performance

| Parameter | Traditional Materials | Advanced Materials | Performance Improvement (%) |

|---|---|---|---|

| Thermal Conductivity | 30 W/mK | 150 W/mK | 400% |

| Durability | 100,000 cycles | 500,000 cycles | 400% |

| Weight | 5 kg | 3 kg | 40% |

| Cost | $500 | $700 | +40% |

Sustainability Trends in Die Mold Manufacturing Processes

The role of sustainability in die mold manufacturing is becoming increasingly critical as industries worldwide strive to reduce their environmental footprints. Recent reports indicate that the global die casting market is projected to reach $78.55 billion by 2026, with sustainability trends significantly influencing this growth. Manufacturers are adopting eco-friendly materials and processes, leading to a more circular economy where waste is minimized, and materials are reused. Technologies such as 3D printing and advanced simulation software are now enabling the creation of molds with lower energy consumption and reduced raw material wastage.

Moreover, innovative cooling techniques and energy-efficient machinery are reshaping die mold production. According to a study from Market Research Future, sustainable practices can improve operational efficiency by up to 30%, translating into significant cost savings over time. Companies are also exploring biodegradable and recyclable mold materials, which not only enhance sustainability but also meet rising consumer demand for eco-friendly products. By focusing on these trends, the die mold industry is not just reshaping its own future but is also contributing positively to broader sustainability goals within manufacturing.

Unlocking Efficiency: Innovations in Die Mold Technology

Future Trends: Smart Technologies and IoT in Die Mold Applications

The integration of smart technologies and the Internet of Things (IoT) in die mold applications represents a significant leap towards enhancing manufacturing efficiency. With the rise of IoT, manufacturers can now embed sensors and connectivity features within die molds, enabling real-time data collection and monitoring. This connectivity allows for immediate analysis of mold performance, facilitating predictive maintenance and reducing downtime. By accessing vital metrics, operators can fine-tune production processes, ensuring optimal functioning of the molds and extending their lifespan.

Additionally, the advent of artificial intelligence (AI) and machine learning is revolutionizing die mold design and production. AI algorithms can analyze vast amounts of data collected from smart molds to predict potential issues and optimize designs for better performance. This not only streamlines the manufacturing process but also leads to significant cost savings by minimizing waste and enhancing the quality of the final products. The future of die mold technology is increasingly linked to these advancements, as the marriage of smart technologies and IoT continues to drive innovation and efficiency in the manufacturing sector.

Related Posts

-

How to Optimize Your Die Mold Production Process for Maximum Efficiency

-

10 Insights for Mastering Die Cast Plastic Techniques

-

Exploring the Differences Between Plastic Injection Molding and Other Manufacturing Processes

-

The Future of Die Casting: Innovations Shaping Tomorrow's Manufacturing

-

How to Choose the Right Die Cast Process for Your Next Project

-

How to Choose the Best Die Cast Die for Your Manufacturing Needs

Copyright © 2025 · All Rights Reserved · Franchino Mold & Engineering